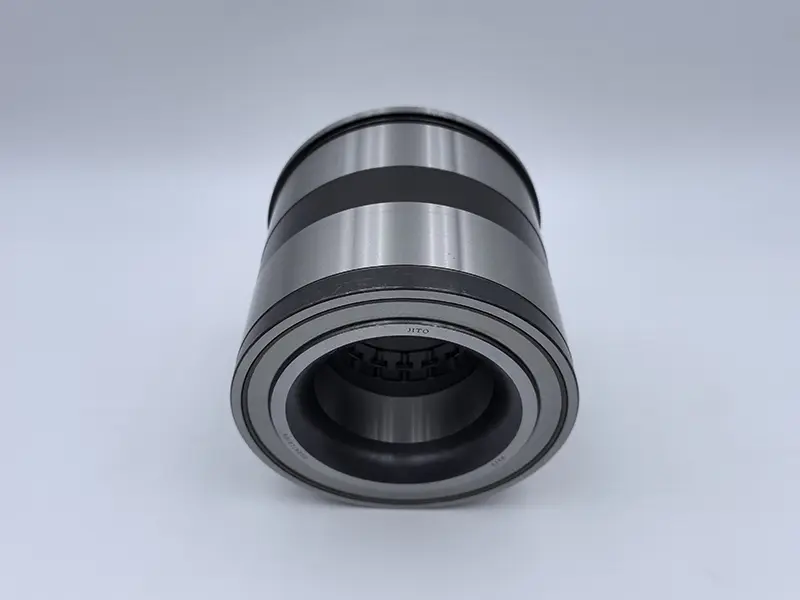

VKBA5423 Truck Bearing Double-row Combined Wheel Hub 94*148*135 Low heat, High Speed Low Noise

Bearing Detail

| Item No. | VKBA5423 |

| Bearing Type | Truck hub bearing |

| Material | Chrome steel GCr15 |

| Precision | P0、P6、P5、P4 |

| Clearance | C0,C2,C3,C4,C5 |

| Noise | V1,V2,V3 |

| Row | Double |

| Raceway type | Crowned raceway |

| Specification | 94*148*135 mm |

| Usage | Car, Heavy Duty Truck, Trailer, Automotive vehicles |

| Brand | JITO or OEM |

| Ball Bearings Feature | Long-life with high quality |

| Low-noise with strict controlling the quality of JITO bearing | |

| High-load by the advanced high-technical design | |

| Competitive price, which has the most valuable | |

| OEM service offered, to meet the customers requirements | |

| Application | Mainly used in commercial vehicles such as trucks and trailers, and can also be used in ships, buses, filtration equipment, gantry milling machines, CNC drilling machines, wind energy equipment, reaction equipment |

| Bearing Package | Pallet,wooden case,commercial packaging or as customers requirement |

| Delivery port | Tianjin or Qingdao |

| Lubrication | Grease or oil |

Product Description

Cage: The cage is made of TH glass fiber reinforced phenolic resin material, which has good wear resistance, self-lubrication and high temperature resistance. It can accurately guide the movement of the rolling element, reduce the collision and friction between the rolling elements, and improve the running accuracy and stability of the bearing.

Usage characteristics: It has high-speed performance and can adapt to the high speed requirements of the wheel hub when the car is driving at high speed. At the same time, it can reduce friction and heat to a certain extent, and improve the efficiency and reliability of the bearing.

High precision: The high-precision manufacturing process and advanced design ensure that the bearing maintains a high precision during operation, making the wheel rotate more smoothly and reducing vibration and noise.

Long life: Made of high-quality chrome steel GCr15 material, it has good wear resistance and fatigue resistance, can withstand the large load generated by the truck during driving, and prolong the service life. In addition, it will be filled with high-quality grease before leaving the factory, which can maintain good lubrication performance under various harsh conditions and further extend the service life of the bearing.

Low noise: After careful design and manufacturing, it can effectively reduce the noise during operation, provide the driver with a quieter driving environment, and reduce driving fatigue.

Good high-speed performance: It can adapt to the high speed requirements of the wheels of the truck when driving at high speed, and ensure the stability and safety of the vehicle when driving at high speed.

Application areas

Mainly used in commercial vehicles such as trucks and trailers, and can also be used in ships, buses, filtration equipment, gantry milling machines, CNC drilling machines, wind energy equipment, reaction equipment, etc.

Maintenance

Regular inspection: Check the use of the bearing at regular intervals, including whether there are abnormal noises, temperature increases, increased vibrations, etc., as well as the degree of wear of the bearing.

Clean and lubricate: Clean the bearing and bearing seat regularly, remove dirt and impurities, and apply an appropriate amount of high-quality grease to reduce friction and wear.

Clearance adjustment: Use tools such as vernier calipers to measure the clearance between the bearing and the bearing seat to ensure that the clearance meets the requirements of the instructions. If the gap is too large or too small, it is necessary to adjust or replace relevant parts in time.

Advantage

Solution

At the beginning, we will have a communication with our customers on their demand, then our engineers will work out an optimum solution based on the customers’ demand and condition.

Quality Control (Q/C)

In accordance with ISO standards, we have professional Q/C staff, precision testing instruments and internal inspection system, the quality control is implemented in every process from material receiving to products packaging to ensure our bearings quality.

Package

Standardized export packing and environment-protected packing material are used for our bearings, the custom boxes, labels, barcodes etc. can also be provided according to our customer’s request.

Logistic

Normally, our bearings will be sent to the customers by ocean transportation due to its heavy weight, airfreight, express is also available if our customers need.

Warranty

We warrant our bearings to be free from defects in material and workmanship for a 12 months period from the shipping date, this warranty is voided by non-recommended use, improper installation or physical damage.

description2