In the ever-evolving field of robotics, the importance of precise and reliable components cannot be overstated. One such critical element is the Miniature Ball Bearings, which offer unmatched versatility and efficiency in various applications. These small yet powerful components play a vital role in enhancing the performance of robotic systems by reducing friction, increasing speed, and ensuring smooth motion. Whether it's in drones, robotic arms, or autonomous vehicles, the strategic incorporation of Miniature Ball Bearings can significantly improve functionality and lifespan. This article delves into the myriad uses of these essential bearings in modern robotics, providing insights into their design, selection, and optimal application methods. By understanding how to effectively integrate Miniature Ball Bearings into robotic projects, engineers and hobbyists alike can push the boundaries of innovation and performance in their designs.

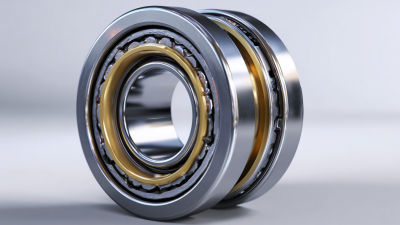

Miniature ball bearings play a crucial role in modern robotics, serving as essential components that enhance the efficiency and precision of robotic systems. These bearings typically feature an outer diameter of less than 1 inch, allowing them to fit into compact designs where space is at a premium. According to a report by MarketsandMarkets, the global ball bearing market is projected to reach over $85 billion by 2026, highlighting the increasing demand for high-performance bearings in various applications, including robotics. The significant advancements in materials and manufacturing processes have further improved the performance characteristics of miniature ball bearings, making them suitable for high speed and low-friction applications.

In robotics, miniature ball bearings are utilized in diverse components such as motors, gears, and articulated joints, contributing to smooth operation and durability. The precision provided by these bearings is paramount; they reduce wear and tear, which not only extends the lifespan of robotic systems but also enhances their functionality. A study from the International Society for Robotics reports that robots equipped with high-quality miniature ball bearings can achieve operational efficiencies of up to 30%, underscoring their importance in the design and engineering of robotic solutions. With ongoing innovations and rising demand, the versatility of miniature ball bearings continues to expand, solidifying their place in the future of robotics.

When evaluating the performance criteria for ball bearings in robotic systems, one must consider several key factors that influence their functionality and reliability. The load capacity is crucial; miniature ball bearings must accommodate both static and dynamic loads without compromising precision. Additionally, the lifespan of these bearings can significantly affect the overall performance of the robotic system. A longer-lasting bearing reduces maintenance needs and downtime, enhancing operational efficiency.

Tips: When selecting ball bearings for robotics, ensure they are made from high-quality materials such as stainless steel or ceramic. These materials exhibit better resistance to wear and corrosion, improving durability. Furthermore, consider the bearing's lubrication system; using the right lubricant can minimize friction and heat generation, leading to smoother operation.

Another essential criterion is the bearing's speed rating, especially in high-performance applications. In robotics, particularly in automated assembly lines and surgical robots, maintaining accuracy at high speeds is vital. Careful attention should be given to the bearing's precision grade, as it directly impacts the robot's positional accuracy and responsiveness, essential attributes for effective operation in complex tasks.

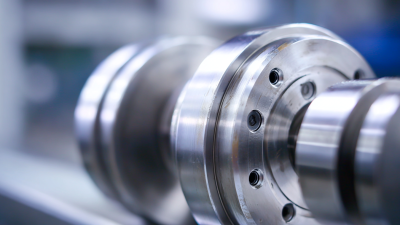

Miniature ball bearings play a crucial role in the advancement of modern robotics, enhancing the performance and efficiency of various robotic systems. One of the key applications of these bearings is in robotic arms, where they facilitate smooth and precise movements. By reducing friction during motion, miniature ball bearings enable robotic arms to execute complex tasks with high accuracy, which is essential in manufacturing and assembly lines.

Another significant application of miniature ball bearings is in drones and aerial robots. These bearings contribute to the lightweight design and agility of flying robots, allowing for better maneuverability and stability during flight. Furthermore, in mobile robots, miniature ball bearings are essential for wheel and joint mechanisms, ensuring optimal performance across varying terrains.

**Tip:** When selecting miniature ball bearings for your robotic project, consider factors such as load capacity and environmental conditions. Choosing the right materials can significantly enhance durability and performance. Additionally, regular maintenance can extend the lifespan of these vital components and ensure reliable operation.

In modern robotics, enhancing mobility is a critical aspect that directly influences the efficiency and versatility of robotic systems. Miniature ball bearings play a pivotal role in achieving this enhanced mobility by reducing friction and allowing for smoother movement in joints and wheels. These compact components are designed to handle both radial and axial loads, enabling robots to perform a wide range of tasks with precision and ease. The integration of miniature ball bearings into robotic designs leads to improved agility, which is essential for applications such as industrial automation, medical robotics, and even consumer robots.

Moreover, the lightweight nature of miniature ball bearings contributes to the overall performance of robotic systems by minimizing weight without sacrificing strength. This reduction in weight is particularly advantageous in mobile robots, where every gram counts towards energy efficiency and speed. As robotics continues to evolve, the demand for more sophisticated and nimble robots has surged, making the strategic integration of miniature ball bearings more relevant than ever. Engineers and designers are increasingly realizing that these small yet powerful components can be the key to unlocking new capabilities in robotic locomotion, allowing robots to navigate complex environments and perform tasks that were once thought to be beyond reach.

| Application Area | Bearing Size (mm) | Load Capacity (N) | Speed Rating (rpm) | Material | Common Use Case |

|---|---|---|---|---|---|

| Robotic Arms | 6x13x5 | 200 | 4500 | Stainless Steel | Precision Movement |

| Drones | 5x10x4 | 150 | 6000 | Plastic/Metal Hybrid | Lightweight Frame |

| Autonomous Vehicles | 7x19x6 | 300 | 5000 | Ceramic | Maneuvering Precision |

| Robotic Surgery | 4x10x4 | 100 | 3000 | Titanium | High Precision Tools |

Maintaining miniature ball bearings is critical in robotics, as these components significantly influence performance and longevity. According to a report by the International Society of Automation, over 30% of equipment failures in robotic systems are attributed to bearing failure. To enhance reliability, implementing a routine maintenance schedule is essential. Regular inspection for signs of wear, corrosion, and contamination can identify potential issues before they escalate. Employing non-intrusive diagnostic tools, like vibration analysis, can also provide insights into the bearing's health, allowing for timely interventions.

Additionally, lubrication is key to minimizing friction and wear in miniature ball bearings. The National Lubricating Grease Institute recommends using high-quality, application-specific lubricants to ensure optimal performance. A study published in the Journal of Manufacturing Science highlights that proper lubrication can extend bearing life by up to 50%. Moreover, choosing the right sealing methods to protect bearings from dust, moisture, and other contaminants can prevent premature failures and maintain the precision required in modern robotics applications. Prioritizing these best practices can lead to better efficiency and fewer downtimes in robotic operations.