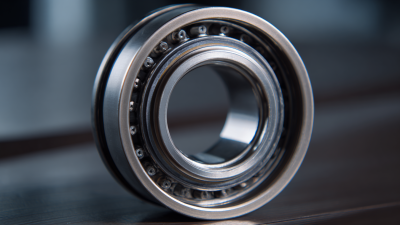

In the competitive landscape of modern manufacturing, the efficiency and longevity of machinery are paramount. One often overlooked component that plays a crucial role in enhancing these aspects is the Bearing Roller. According to a recent report by MarketsandMarkets, the global bearings market is projected to reach USD 92.20 billion by 2024, driven significantly by advancements in industrial automation and machinery. Bearing Rollers, known for their ability to reduce friction and wear, contribute to smoother operation and increased reliability of equipment. The incorporation of Bearing Rollers is not just a maintenance strategy; it can lead to improved production rates and reduced downtime. This blog will explore seven unexpected benefits of utilizing Bearing Rollers in your machinery, shedding light on their pivotal role in optimizing performance and ensuring long-lasting equipment reliability.

Bearing rollers play a critical role in enhancing load distribution across machinery, offering significant advantages that can lead to improved operational efficiency. According to a report from the American Society of Mechanical Engineers (ASME), machinery that employs bearing roller technology can see a reduction in friction by up to 30%, which directly translates to reduced wear and extended service life. This improved load distribution helps to mitigate stress concentrations on mechanical components, ensuring that parts withstand the rigors of heavy operation without failure.

Furthermore, studies from the International Journal of Advanced Manufacturing Technology indicate that utilizing bearing rollers can increase load-carrying capacity by approximately 25% compared to traditional bearing systems. This enhanced capacity allows for more robust machinery operation, accommodating heavier loads and increasing productivity. Additionally, the balanced weight distribution provided by bearing rollers contributes to smoother operation, decreasing vibration by up to 15%, which enhances the overall reliability and longevity of the equipment. These benefits underscore the importance of adopting bearing roller systems for any machinery aiming for operational excellence.

| Benefit | Description | Impact |

|---|---|---|

| Enhanced Load Distribution | Bearing rollers distribute loads evenly across machinery components. | Reduces wear and tear, prolonging component life. |

| Increased Efficiency | Lower friction leads to better machinery performance. | Enhances overall productivity and energy savings. |

| Noise Reduction | Rollers provide smoother operation, minimizing operational noise. | Improves working environment and comfort. |

| Thermal Management | Better load distribution helps in maintaining optimal temperatures. | Reduces risk of overheating and failure. |

| Versatility | Bearing rollers can be used in diverse applications across industries. | Offers flexible solutions for various machinery types. |

| Longer Maintenance Intervals | Durable materials and designs prolong the time between maintenance. | Saves time and reduces downtime costs. |

| Enhanced Safety | Stable load handling minimizes the risk of machinery accidents. | Improves workplace safety and reduces liability risks. |

When it comes to enhancing machinery performance, bearing rollers play a pivotal role by significantly improving efficiency and reducing friction. These cylindrical components allow for smooth rotation and linear motion, which minimizes resistance between moving parts. Lower friction not only leads to less energy consumption but also extends the lifespan of the machinery, making it a cost-effective solution for manufacturers.

One of the unexpected benefits of using bearing rollers is their ability to enhance overall machinery stability. With reduced vibration and noise levels, equipment operates more quietly and reliably. This stability can lead to improved precision in applications where accuracy is critical, making bearing rollers essential in industries ranging from automotive to aerospace. Additionally, as these rollers facilitate smoother movements, they can help prevent wear and tear on surrounding components, further enhancing the operational longevity of the entire system.

In the industrial machinery landscape, reducing maintenance costs is paramount for enhancing operational efficiency. One unexpected benefit of using bearing rollers is their ability to lower these costs significantly. By integrating bearing rollers into machinery design, companies can enjoy longer service intervals and minimize downtime associated with repairs and replacements. This efficiency is largely attributed to the superior load-bearing capabilities of combined bearing types—those featuring one row of needle bearings and one row of ball bearings. This design allows for better weight distribution and improved performance under heavy radial and bidirectional axial loads.

Moreover, the evolution of self-lubricating bearings plays a crucial role in reducing maintenance overheads. As the market for these bearings is projected to grow significantly in the coming years, businesses increasingly recognize their long-term value. With reduced friction and extended lifespans, self-lubricating bearings not only cut down on the need for manual lubrication but also enhance overall machine reliability. By adopting these advanced bearing solutions, industries are poised to optimize their operations while simultaneously enjoying the benefits of cost-effective maintenance.

In the world of machinery, noise is often seen as an inevitable byproduct of mechanical movement. However, the application of bearing rollers has ushered in a new era of noise reduction in various industrial operations. These innovative components not only facilitate smoother motion but also significantly dampen vibrations, leading to quieter machinery. By minimizing friction and eliminating rattling, bearing rollers create an environment where operators can focus on their tasks without the distraction of relentless clamor.

The quiet revolution brought about by bearing rollers is particularly noticeable in applications that demand precision and tranquility, such as in robotics and medical equipment. Reduced noise levels can enhance workplace safety and productivity, as well as improve the user experience for operators and end-users. Furthermore, the incorporation of bearing rollers contributes to the longevity of machinery, as less wear over time translates to lower maintenance costs and fewer disruptions caused by mechanical failures. As industries increasingly prioritize efficiency and comfort, bearing rollers have become indispensable in fostering a more serene and reliable working environment.

The use of bearing rollers in machinery can lead to significant benefits, including noise reduction. This chart illustrates the impact of different benefits associated with using bearing rollers in various types of machinery.

The integration of bearing rollers in machinery has become increasingly popular due to the significant durability and lifespan improvements they offer. Unlike traditional bearing systems, bearing rollers are designed to handle higher loads while reducing friction. This innovative design leads to less wear and tear on components, allowing machines to operate smoothly over longer periods. As a result, businesses can enjoy enhanced operational efficiency and reduced maintenance costs.

Moreover, the use of bearing rollers can minimize downtime in production processes. With their ability to withstand extreme conditions and resist mechanical failures, machines equipped with bearing rollers are less likely to experience unexpected breakdowns. This reliability not only boosts productivity but also extends the overall lifespan of the equipment. By investing in bearing roller technology, industries can ensure their machinery remains robust and efficient, ultimately translating to greater long-term savings and performance advantages.