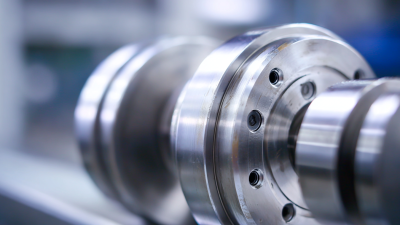

In the rapidly evolving landscape of modern machinery, the role of bearings is critical, and among them, the Double Groove Ball Bearing stands out as a transformative component. Renowned industry expert Dr. John H. Miller, a leading figure in bearing technology, once stated, "The efficiency and performance of machinery are significantly enhanced through the use of Double Groove Ball Bearings, which offer superior load distribution and reduced friction." This innovation not only addresses the growing demands for precision and reliability but also paves the way for advancements across various sectors, including automotive, aerospace, and industrial applications.

With their unique design featuring two grooves, Double Groove Ball Bearings provide increased stability and improved operational efficiency, making them essential in high-speed and high-load environments. As manufacturers seek to optimize their machinery, understanding the intricacies of this component becomes paramount. This guide will delve into the mechanics, applications, and benefits of Double Groove Ball Bearings, illustrating how they revolutionize the performance capabilities of modern equipment and empower industries to achieve greater productivity and reliability.

Double groove ball bearings play a crucial role in modern machinery, significantly reducing friction and wear, which leads to enhanced operational efficiency. Recent theoretical and experimental studies highlight the importance of understanding the thermomechanical characteristics of double-row bearings, especially in automotive applications. The research emphasizes that controlling the thermodynamic properties of these bearings can optimize performance under varying operational conditions, ultimately contributing to longer service life and reduced maintenance costs.

In a world where machinery reliability is paramount, double groove ball bearings are revolutionizing designs by providing superior load distribution and stability. Analytical data indicate that these bearings can decrease friction by as much as 30% compared to traditional designs, thus lowering the energy consumption of machinery. As industries continue to innovate, leveraging bearings that minimize wear is not just beneficial but essential.

Tips: When selecting double groove ball bearings, consider their material composition and lubrication methods, as these can significantly affect their performance and longevity. Regular maintenance and monitoring of temperature changes in bearings can prevent premature failure, ensuring a smoother operation.

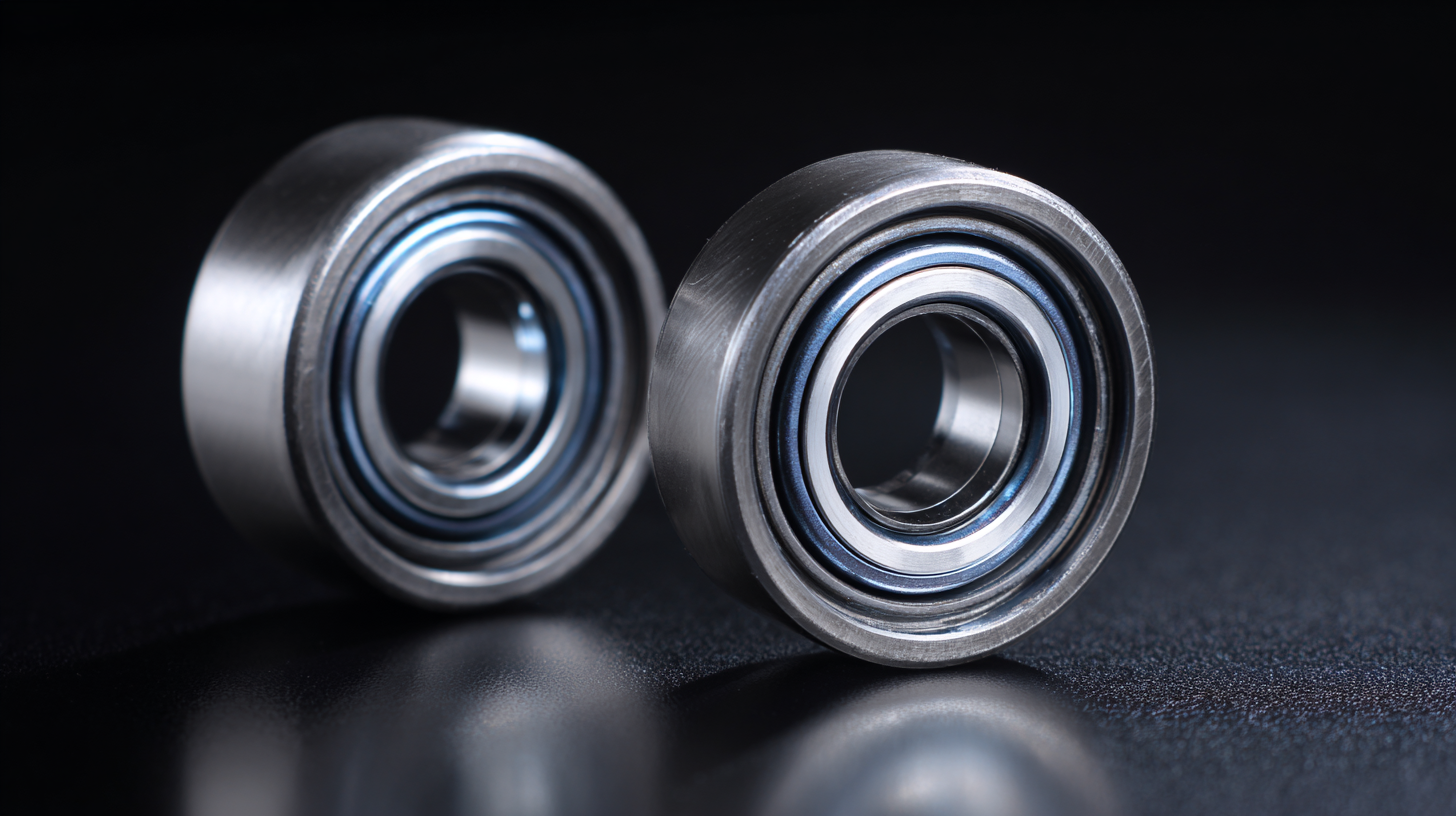

Double groove ball bearings have become essential components in modern industrial applications due to their numerous advantages. One of the key benefits is their ability to support both axial and radial loads effectively. This dual load capability allows machinery to operate more efficiently and with less wear, reducing maintenance costs and downtime. In environments where space is limited, the compact design of double groove ball bearings provides a significant advantage, enabling engineers to save design space while enhancing performance.

Double groove ball bearings have become essential components in modern industrial applications due to their numerous advantages. One of the key benefits is their ability to support both axial and radial loads effectively. This dual load capability allows machinery to operate more efficiently and with less wear, reducing maintenance costs and downtime. In environments where space is limited, the compact design of double groove ball bearings provides a significant advantage, enabling engineers to save design space while enhancing performance.

Another important benefit is the enhanced durability and longevity of machinery that utilizes these bearings. With improved load distribution and reduced friction, double groove ball bearings are less susceptible to overheating and wear over time. This characteristic not only extends the service life of the bearings themselves but also contributes to the overall reliability of the equipment. Industries ranging from manufacturing to automotive are increasingly adopting these bearings, leading to higher productivity rates and improved operational efficiency.

Double groove ball bearings have emerged as a leading solution in modern machinery, surpassing their single groove counterparts in various performance metrics. According to a recent study by the International Journal of Mechanical Engineering, double groove bearings can reduce friction by up to 15%, enhancing the efficiency of machines in high-speed applications. This increase in efficiency not only leads to lower energy consumption but also extends the lifespan of the machinery. The robust design of double groove bearings allows them to handle greater axial and radial loads, with reports indicating an improvement in load capacity by 20% compared to single groove bearings.

When considering longevity, double groove ball bearings generally exhibit superior wear resistance due to their enhanced contact area. A report from the Bearing Manufacturers Association highlights that devices equipped with double groove bearings can experience up to 40% less wear over time, leading to significantly reduced maintenance costs. This makes them an ideal choice for industries where reliability is paramount, such as automotive and aerospace sectors.

Tips: When selecting the right bearing for your application, consider not only the load capacity but also the operational environment. Ensuring proper lubrication can further enhance longevity and performance. Additionally, regularly monitoring the bearings for signs of wear can prevent unforeseen machinery failures.

Recent advancements in materials and technology have significantly improved the efficiency of double groove ball bearings, making them essential components in modern machinery. The transition from traditional materials to high-performance composites and alloys has conferred several advantages, including increased load capacity and reduced friction. Innovations such as ceramic balls within the bearings offer enhanced durability and resistance to wear, ultimately extending the service life of machinery. This shift not only optimizes operational efficiency but also leads to lower maintenance costs.

Tips: When selecting double groove ball bearings, consider the application environment and the specific loads they will encounter. This ensures you choose the right material that will withstand potential wear and tear. Regular maintenance, including lubrication and inspections, can greatly enhance the longevity of these bearings, maximizing your investment.

As the global bearings market continues to expand, projected to grow from USD 50.16 billion in 2025 to USD 97.10 billion by 2030, the emphasis on technological advancement in bearing design will be pivotal. Companies leveraging these innovations will likely hold a significant competitive advantage, allowing for more precise and reliable machinery performance across various industries.

| Specification | Material | Load Capacity (N) | Speed Rating (RPM) | Application |

|---|---|---|---|---|

| 6200 Series | High Carbon Steel | 2000 | 15000 | Electric Motors |

| 6300 Series | Stainless Steel | 2500 | 12000 | Agricultural Equipment |

| 6400 Series | Ceramic Hybrid | 3000 | 20000 | Heavy Machinery |

| 6800 Series | Plastic | 1500 | 10000 | Consumer Electronics |

Double groove ball bearings have increasingly become a game-changer in manufacturing environments, streamlining operations and significantly enhancing efficiency. A recent industry report highlighted that the adoption of double groove ball bearings can improve energy efficiency by up to 15%, a crucial factor as companies seek to reduce operational costs and minimize environmental impact. Their design allows for better load distribution, which not only prolongs the lifespan of machinery but also reduces maintenance downtime, making them a pivotal component in modern machinery.

Real-life case studies further illustrate the transformative impact of these bearings. Manufacturers utilizing double groove ball bearings have reported a remarkable 20% increase in production rates, translating to millions in potential revenue gains. For instance, a leading automotive supplier implemented double groove ball bearings in their conveyor systems, resulting in a substantial reduction in friction-related wear and tear. This not only optimized their production lines but also enhanced overall equipment effectiveness (OEE) by over 10%, showcasing how strategic upgrades can lead to significant operational advancements. As more organizations recognize the potential of double groove ball bearings, the landscape of modern manufacturing continues to evolve.