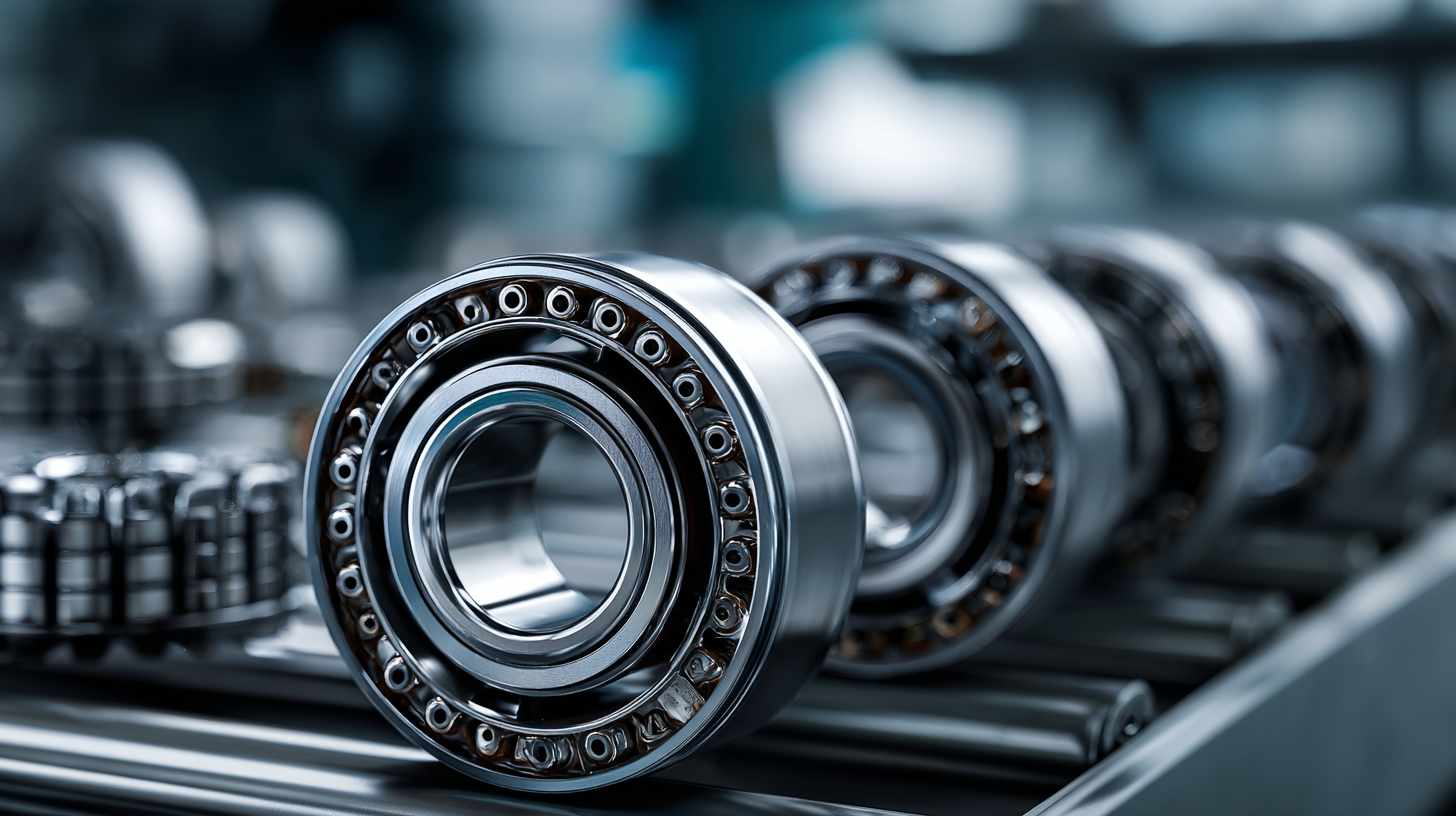

In the realm of industrial machinery, the efficiency and reliability of equipment are paramount for operational success. Tapered Roller Bearings play a critical role in enhancing these attributes, providing optimal load distribution and reducing friction in rotating machinery. According to a report by MarketsandMarkets, the global bearing market is projected to reach $95.5 billion by 2025, with tapered roller bearings accounting for a significant share due to their superior performance in high-load applications. These bearings are designed to accommodate both radial and axial loads, making them ideal for heavy machinery such as construction equipment, trucks, and industrial motors. As industries continue to seek greater productivity and cost-effectiveness, understanding the benefits of Tapered Roller Bearings becomes essential for manufacturers aiming to improve operational efficiency and equipment longevity.

Tapered roller bearings are essential components in industrial machinery, known for their ability to handle both radial and axial loads. There are various types of tapered roller bearings, each designed for specific applications, which enhance machinery efficiency. For instance, single-row tapered roller bearings are widely used in automotive applications, including wheel hubs and transmissions, due to their compact design and ability to accommodate moderate to heavy loads.

Tapered roller bearings are essential components in industrial machinery, known for their ability to handle both radial and axial loads. There are various types of tapered roller bearings, each designed for specific applications, which enhance machinery efficiency. For instance, single-row tapered roller bearings are widely used in automotive applications, including wheel hubs and transmissions, due to their compact design and ability to accommodate moderate to heavy loads.

In contrast, double-row tapered roller bearings provide increased load-carrying capacity and are often found in heavy machinery like excavators and industrial gearboxes. Their design allows for optimal clearance adjustments and support for high-speed operations. Additionally, custom-designed tapered roller bearings cater to specialized industries such as aerospace and mining, where they are engineered to withstand extreme conditions while ensuring reliable performance. The versatility of tapered roller bearings makes them a vital choice in various industries, contributing significantly to machinery longevity and operational efficiency.

Tapered roller bearings offer significant advantages for operational efficiency in industrial machinery. One of the key benefits is their ability to handle both radial and axial loads, which is crucial for applications where machines face multidirectional forces. This functionality not only enhances the stability of machinery but also extends component life by distributing stress more evenly across the bearing surfaces.

Tips: When selecting tapered roller bearings for high-performance applications, it is essential to consider the bearing's load ratings and the specific load conditions of your machinery. Additionally, ensuring proper lubrication can significantly reduce friction and wear, further improving efficiency.

Another advantage of tapered roller bearings is their compact design, which allows for smaller machinery footprints without compromising performance. This design versatility is particularly beneficial in industries that require space-saving solutions while maintaining high load-carrying capabilities.

Tips: Regular maintenance and inspection of tapered roller bearings can help identify wear issues early, preventing costly downtimes and enhancing overall productivity in operations. Implementing a scheduled lubrication routine can also maintain optimal performance levels, ensuring your machinery continues to operate efficiently.

Tapered roller bearings (TRBs) are widely recognized for their ability to handle both radial and axial loads, which sets them apart from other bearing types like ball bearings or spherical bearings. According to the “Bearings Market Research Report” published by MarketsandMarkets, the demand for TRBs is projected to grow at a CAGR of 6.5% from 2021 to 2026, largely driven by their efficiency in heavy industrial applications. This ability to endure high loads with minimal friction translates to reduced energy consumption and increased operational lifespan, making them a preferred choice in sectors such as automotive, aerospace, and manufacturing.

In a comparative analysis, TRBs outperform ball bearings in applications requiring high radial load capacities. A study from the American Bearing Manufacturers Association notes that TRBs can support load ratings that are 20-30% higher than comparable ball bearings while maintaining lower operating temperatures. This efficiency not only ensures longer service intervals but also decreases maintenance costs, contributing significantly to overall machinery efficiency. Industries are increasingly favoring TRBs as they strive for sustainability and productivity, illustrating their critical role in modern industrial machinery.

Tapered roller bearings play a crucial role in enhancing the efficiency of industrial machinery, but their longevity depends significantly on effective maintenance. Regular inspection and lubrication are essential for preventing premature wear and ensuring optimal performance. According to a report by the Society of Tribologists and Lubrication Engineers, up to 70% of bearing failures can be attributed to inadequate lubrication practices. Maintaining the correct lubricant level and choosing the appropriate type based on operating conditions can significantly improve the lifespan of tapered roller bearings.

Tips for Maintenance:

By implementing these best practices, industries can not only prolong the life of tapered roller bearings but also enhance the overall efficiency of machinery, resulting in fewer downtimes and reduced operational costs. A study by the American Bearing Manufacturers Association reported that effective maintenance can lead to a reduction in bearing failures by up to 30%, underscoring the importance of proper care.

The evolution of tapered roller bearing technology has significantly enhanced their role in industrial machinery. Modern innovations focus on optimizing roller geometry and material composition to increase load capacity and reduce friction. By utilizing advanced manufacturing techniques, such as precision machining and heat treatment, manufacturers can produce tapered roller bearings with tighter tolerances, leading to improved performance and durability. These enhancements not only extend the lifespan of the bearings but also contribute to smoother operation in various applications.

Additionally, the integration of smart technology into tapered roller bearings is revolutionizing their design and functionality. Sensors can now be embedded to monitor temperature, vibration, and load conditions in real time. This data allows for predictive maintenance, minimizing downtime and reducing operational costs. Such advancements ensure that industrial machinery operates at peak efficiency, adapting to changing loads and conditions seamlessly. As the demand for higher efficiency and reliability in industrial applications grows, the continuous development of tapered roller bearing technology remains a key factor in achieving these goals.