In the ever-evolving landscape of modern machinery, Tapered Roller Bearings (TRBs) have emerged as pivotal components that significantly enhance performance and efficiency across various applications. According to a report by MarketsandMarkets, the global bearings market is projected to grow from $80 billion in 2021 to over $110 billion by 2026, with TRBs playing a vital role due to their superior load-bearing capacities and operational precision. Industries ranging from automotive to aerospace increasingly rely on tapered roller bearings to withstand higher loads and reduce friction, thus improving energy efficiency and prolonging equipment lifespan. This blog will explore the essential functions, applications, and future trends of tapered roller bearings, highlighting their crucial contributions to the advancement of modern machinery.

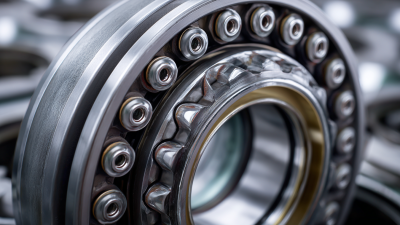

Tapered roller bearings are crucial components in modern machinery, significantly enhancing mechanical efficiency. These bearings are designed to handle both radial and axial loads, allowing them to support heavy-duty applications with ease. By optimizing the contact between the roller and the raceway, tapered roller bearings reduce friction and wear, leading to prolonged equipment life and improved performance. In industries ranging from automotive to aerospace, their role cannot be overstated, as they ensure smoother operation and higher productivity.

**Tip:** When selecting tapered roller bearings for your machinery, always consider the load capacity and operating conditions. Choosing the right size and material can dramatically influence performance and durability.

Moreover, the installation and maintenance of tapered roller bearings are equally important in maximizing efficiency. Properly aligned bearings help to distribute loads evenly, preventing premature failure. Regular inspections can identify issues early, ensuring that your machinery operates at peak performance.

**Tip:** Regularly check for signs of wear or misalignment in your tapered roller bearings. Establishing a routine maintenance schedule can save costs and reduce downtime caused by unexpected breakdowns.

| Dimension (inches) | Load Capacity (lbs) | Operating Speed (RPM) | Temperature Range (°F) | Typical Applications |

|---|---|---|---|---|

| 1.5 x 3.5 | 1500 | 3600 | -20 to 250 | Automotive, Industrial Gearboxes |

| 2.0 x 4.0 | 2500 | 3200 | -10 to 300 | Construction Machinery, Mining Equipment |

| 2.5 x 6.0 | 3000 | 2800 | 0 to 350 | Wind Turbines, Heavy Duty Trucks |

| 3.0 x 7.0 | 4500 | 2400 | -40 to 300 | Agricultural Equipment, Marine Applications |

| 3.5 x 8.0 | 5000 | 2200 | -20 to 350 | Railway Systems, Construction Machinery |

Tapered roller bearings are integral components in modern machinery, designed to support both radial and axial loads. However, despite their robustness, these bearings can encounter several common issues that may lead to operational inefficiencies. According to a report by the National Lubricating Grease Institute (NLGI), improper lubrication is one of the primary causes of tapered roller bearing failure, accounting for approximately 30% of all bearing-related issues. Insufficient or contaminated lubricant can lead to increased friction, heat generation, and premature wear, ultimately affecting the overall performance of machinery.

Tapered roller bearings are integral components in modern machinery, designed to support both radial and axial loads. However, despite their robustness, these bearings can encounter several common issues that may lead to operational inefficiencies. According to a report by the National Lubricating Grease Institute (NLGI), improper lubrication is one of the primary causes of tapered roller bearing failure, accounting for approximately 30% of all bearing-related issues. Insufficient or contaminated lubricant can lead to increased friction, heat generation, and premature wear, ultimately affecting the overall performance of machinery.

Another prevalent problem is misalignment, which can lead to uneven load distribution and increased stress on the bearing surfaces. The American Society of Mechanical Engineers (ASME) highlights that misalignment can reduce bearing life by up to 60%, underscoring the importance of precise installation and regular monitoring for proper alignment. Additionally, external factors such as contaminants and vibrations can exacerbate these issues, leading to further degradation of the bearing over time. Addressing these challenges is crucial for the longevity and reliability of equipment that depends on tapered roller bearings.

Tapered roller bearings are critical components in various modern machinery, providing the necessary support and facilitating smooth rotational movement under heavy loads. However, like any mechanical element, they are susceptible to failure if not diagnosed and maintained properly. Common indicators of potential issues include unusual noises, vibrations, and excessive heat. Regular monitoring of these symptoms can help in identifying problems early and preventing catastrophic failures that could lead to costly downtime.

To effectively prevent tapered roller bearing failures, it’s essential to implement a robust maintenance schedule. This includes routine inspections that focus on lubrication levels, alignment, and cleanliness. Proper lubrication not only reduces friction but also dissipates heat, which can prolong bearing life. Additionally, employing condition monitoring technologies can provide real-time data on vibration and temperature, allowing for predictive maintenance. By adopting these proactive measures, industries can significantly enhance the reliability of their machinery and ensure optimal performance.

Tapered roller bearings play a critical role in the performance and reliability of modern machinery. Their unique design allows them to handle both radial and axial loads, making them a popular choice in various applications, from automotive to aerospace. However, the quality of these bearings directly impacts machinery performance, influencing factors such as efficiency, durability, and maintenance costs. High-quality tapered roller bearings reduce friction, enhance resistance to wear, and improve overall operational smoothness, which is essential for machinery that operates under high-stress conditions.

When selecting tapered roller bearings, it is imperative to consider not only the specification and design but also the manufacturing standards and materials used. Bearings produced with precision and strict quality control are less prone to failure and can withstand greater loads than those made with inferior craftsmanship. The longevity and performance of the equipment largely depend on these components; therefore, investing in high-quality tapered roller bearings ensures optimal performance, reduces downtime, and ultimately saves costs in the long run. As industries continue to evolve and machinery becomes more advanced, the quality of the components we choose becomes more crucial than ever.

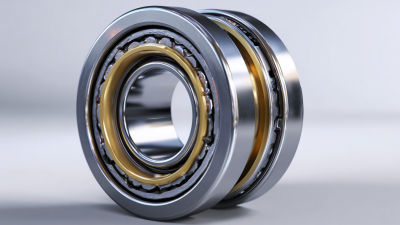

Tapered roller bearings are crucial components in modern machinery, offering unparalleled efficiency and performance. Innovations in their design and manufacturing processes have significantly enhanced their reliability and durability. According to a report by Market Research Future, the global tapered roller bearing market is expected to grow at a compound annual growth rate (CAGR) of 7.0% from 2020 to 2026. This growth can largely be attributed to advancements in materials and precision engineering, allowing for lighter and stronger bearings that can handle higher loads and speeds.

Manufacturers are increasingly utilizing computer-aided design (CAD) and simulation technologies to create tapered roller bearings with improved geometries. This not only optimizes performance but also contributes to reduced noise and vibration, enhancing the overall user experience in machinery. Additionally, the implementation of advanced surface treatments, such as nitriding and coating, has been shown to increase wear resistance and extend the service life of these bearings.

**Tip:** When selecting tapered roller bearings, consider the specific load and speed requirements of your application. Ensuring proper alignment and installation can also prevent premature wear. Another useful tip is to regularly monitor bearing temperature and performance; early detection of anomalies can lead to timely maintenance and prevent potential breakdowns.

This chart illustrates the advancements in tapered roller bearing design and manufacturing over the past decade, highlighting key innovations in load capacity, durability, and application areas.