Tapered Roller Bearings (TRBs) play a critical role in various industrial applications due to their ability to handle both radial and axial loads efficiently. According to a recent report by Mordor Intelligence, the global tapered roller bearing market was valued at approximately USD 6.5 billion in 2021 and is projected to grow at a CAGR of around 5.2% from 2022 to 2027, driven by the increasing demand in sectors such as automotive, aerospace, and heavy machinery. These bearings are designed to provide a higher load-carrying capacity and improved performance compared to standard bearings, making them essential for high-speed and high-load applications. Understanding the different types of tapered roller bearings and their specific applications is crucial for engineers and manufacturers aiming to optimize machinery performance and reliability. This blog will explore the various types of tapered roller bearings, their unique designs, and tips for selecting the right bearing for specific applications.

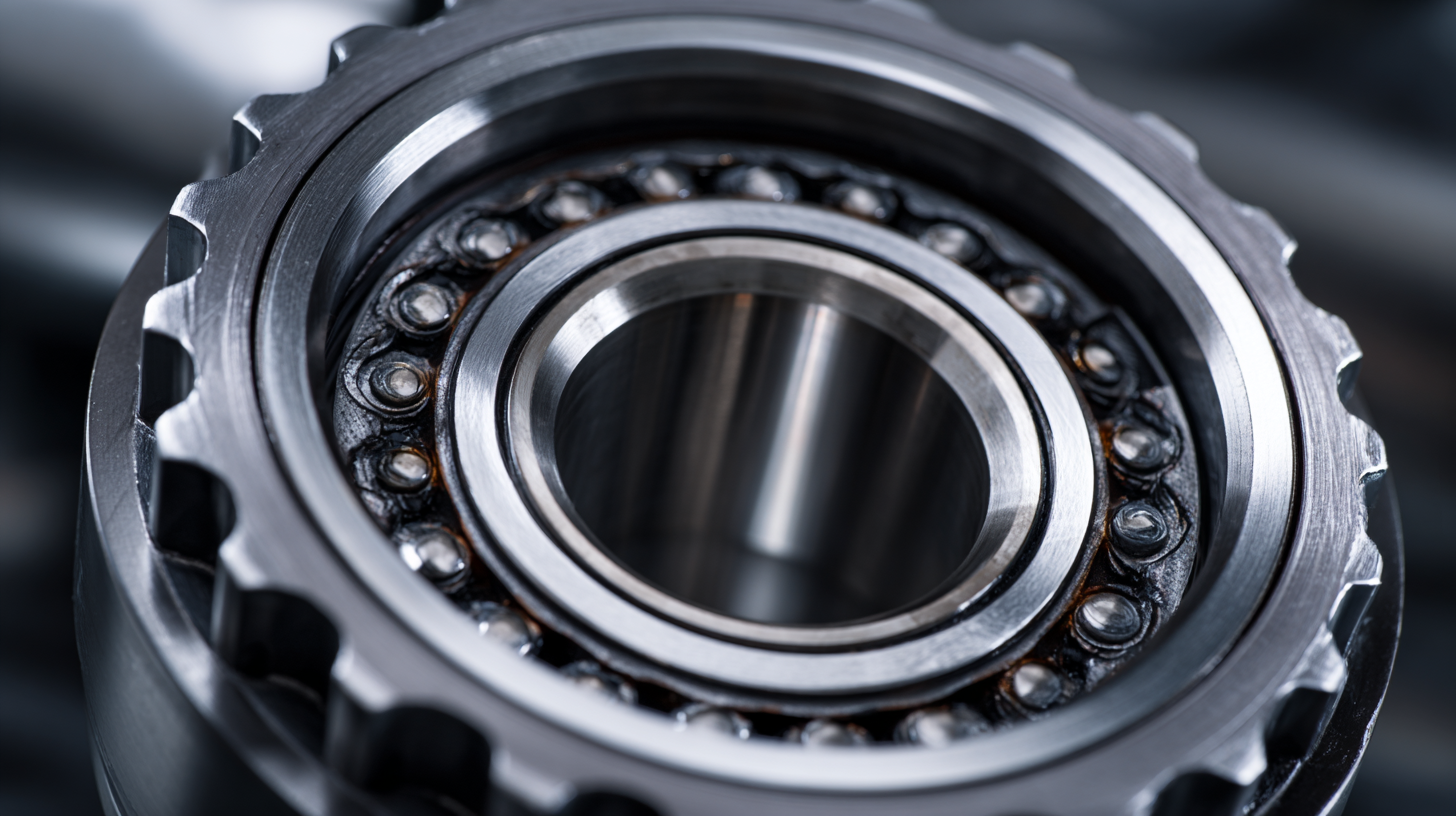

Tapered roller bearings are essential components in various machinery, designed to accommodate radial and axial loads simultaneously. Their unique design, featuring tapered inner and outer raceways, provides an efficient load distribution that enhances performance and longevity. There are several types of tapered roller bearings, each tailored for specific applications. The most common include single-row, double-row, and four-row tapered roller bearings, each offering distinct advantages for different operational demands.

Single-row tapered roller bearings are the most widely used type, ideal for applications where space is limited but reliable performance is crucial. They are commonly found in automotive wheel hubs, gearboxes, and various industrial machines. Double-row tapered roller bearings, on the other hand, have two rows of rollers that can support heavier loads and are typically used in applications such as construction equipment and mining machinery. For applications requiring maximum load-carrying capacity and stability, four-row tapered roller bearings are the go-to choice, often utilized in heavy-duty machinery, such as paper mills and steel mills, where robust performance is essential.

Tapered roller bearings are essential components utilized across various industries owing to their unique ability to handle both radial and axial loads. As the global bearings market is projected to grow from USD 50.16 billion in 2025 to an impressive USD 97.10 billion, the demand for high-performance tapered roller bearings is expected to rise significantly. These bearings are particularly vital in automotive applications, where they enhance the efficiency and durability of wheel hubs and transmission systems, ensuring a smooth operation even under heavy loads.

Tapered roller bearings are essential components utilized across various industries owing to their unique ability to handle both radial and axial loads. As the global bearings market is projected to grow from USD 50.16 billion in 2025 to an impressive USD 97.10 billion, the demand for high-performance tapered roller bearings is expected to rise significantly. These bearings are particularly vital in automotive applications, where they enhance the efficiency and durability of wheel hubs and transmission systems, ensuring a smooth operation even under heavy loads.

In the mining industry, the innovative use of tapered roller bearings contributes to the operational reliability of machinery. For instance, large spherical roller bearings with bore diameters exceeding 1.25 meters have been engineered to withstand extreme conditions, showcasing advancements in bearing technology. Moreover, with the growing emphasis on sustainability, the development of new bearing prototypes from advanced materials signifies a shift towards greener manufacturing practices. The integration of tapered roller bearings in sectors such as construction and aerospace further underscores their versatility and importance in enhancing performance across diverse applications.

Tapered roller bearings are essential components in various applications, particularly in heavy machinery and automotive industries. Understanding performance metrics such as load ratings and bearing life is crucial for optimizing their usage. Load ratings are defined based on the dynamic and static capacities of a bearing, which reflect its ability to bear loads without deformation. According to the American Bearing Manufacturers Association, a properly selected tapered roller bearing can handle radial loads while supporting axial loads in both directions, making it an ideal choice for applications like wheel hubs and gearbox assemblies.

Evaluating bearing life is also vital. The bearing life, often expressed in L10 hours, signifies the time at which 90% of bearing samples will still be operational under specific load and speed conditions. A study conducted by the National Institute of Standards and Technology indicated that enhancing lubricant quality and adhering to recommended operating parameters can significantly extend the bearing life—sometimes by over 30%. By carefully analyzing load ratings and implementing best practices, engineers can ensure that tapered roller bearings function reliably and efficiently, ultimately leading to improved performance and reduced maintenance costs in various industrial applications.

| Bearing Type | Dynamic Load Rating (kN) | Static Load Rating (kN) | Limiting Speed (rpm) | Bearing Life (L10, hours) |

|---|---|---|---|---|

| Single Row Tapered Roller Bearing | 50 | 65 | 3000 | 2000 |

| Double Row Tapered Roller Bearing | 80 | 105 | 2500 | 2500 |

| Four Row Tapered Roller Bearing | 150 | 180 | 1500 | 3000 |

| Tapered Roller Bearing with Seals | 65 | 85 | 2700 | 2200 |

When designing tapered roller bearings, the choice of materials plays a crucial role in ensuring their performance and longevity. The primary materials used in the construction of these bearings often include high-quality steels, such as chromium steel, which offers excellent hardness and wear resistance. By selecting the right grade of steel, manufacturers can enhance the bearing’s ability to withstand heavy radial and axial loads, ultimately improving efficiency and reducing maintenance costs.

In addition to traditional steels, advancements in material technology have led to the incorporation of alternative materials like

ceramic and polymer composites in tapered roller bearings. Ceramic materials, for example, exhibit lower density and higher hardness, which can significantly reduce friction and weight, making them ideal for high-speed applications. Meanwhile, polymer composites can provide enhanced corrosion resistance and lower thermal conductivity, allowing for improved performance in harsh environments. Ultimately, understanding the material considerations in tapered roller bearing design is vital for optimizing their functionality in various industrial applications.

The technology surrounding tapered roller bearings has seen significant advancements in recent years, driven by the increasing demands of various industries such as automotive, aerospace, and heavy machinery. According to a market research report by Grand View Research, the global tapered roller bearing market is projected to reach USD 11.2 billion by 2030, growing at a CAGR of 5.1% from 2023. This growth is largely attributed to innovations aimed at enhancing efficiency, durability, and load capacity.

Recent trends highlight the integration of advanced materials and manufacturing processes in tapered roller bearings. For instance, the adoption of high-performance polymers and composites is gaining traction, as these materials offer lower weight and improved resistance to wear and corrosion. Additionally, the implementation of precision engineering techniques has enabled manufacturers to produce tapered roller bearings that maintain stricter tolerances, enhancing their overall performance in demanding applications. As industries move towards automation and smart technologies, the development of connected bearing solutions is also emerging, offering real-time monitoring capabilities to optimize maintenance and reduce downtime. This convergence of technology in tapered roller bearing design represents a crucial step in meeting the evolving needs of today's machinery and equipment.