In the world of precision engineering and manufacturing, V Groove Roller Bearings play a crucial role in ensuring optimal performance and efficiency in various applications. According to a recent industry report by MarketsandMarkets, the global bearing market is projected to reach over $100 billion by 2025, driven by the rising demand in sectors such as automotive, aerospace, and industrial machinery.

The V Groove Roller Bearing segment, known for its unique design that facilitates smooth linear motion alongside rotary motion, is witnessing significant growth due to its ability to enhance load handling capabilities. Furthermore, the increasing focus on obtaining global trade certifications, such as ISO and CE, underscores the industry's commitment to quality and safety standards, making it imperative for manufacturers to stay abreast of the latest trends and alternative types in the bearing market. As we delve deeper into the secrets of V Groove Roller Bearings, we will uncover the innovations and strategies that are shaping this vital component of modern engineering.

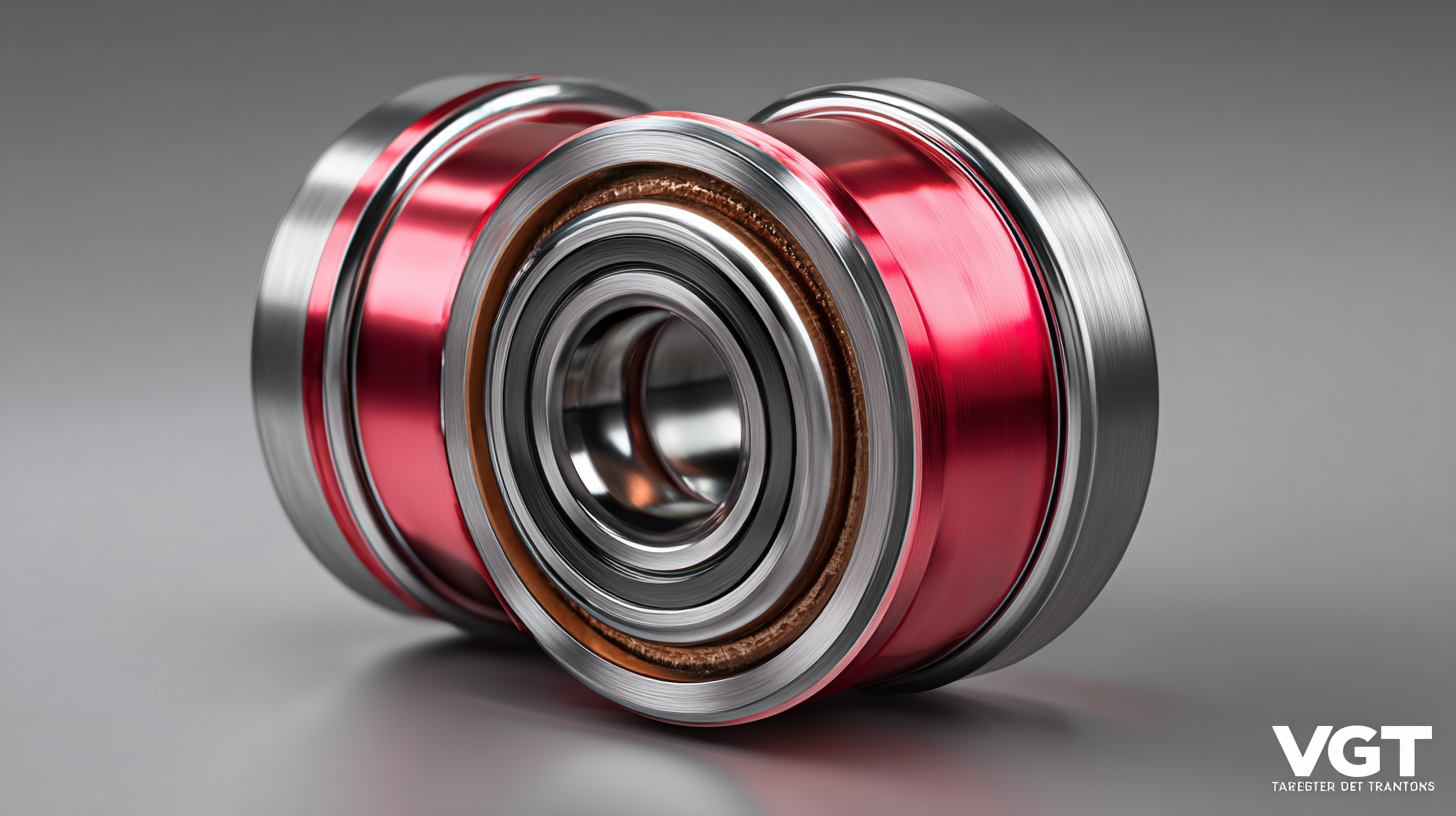

V groove roller bearings are essential components in various applications, particularly in the movement of machinery and equipment. These bearings are specifically designed with a V-shaped groove, allowing them to smoothly navigate along tracks, making them ideal for linear motion systems. One of their key features is the ability to support heavy loads while maintaining a low friction coefficient, which enhances efficiency and reduces wear and tear over time.

V groove roller bearings are essential components in various applications, particularly in the movement of machinery and equipment. These bearings are specifically designed with a V-shaped groove, allowing them to smoothly navigate along tracks, making them ideal for linear motion systems. One of their key features is the ability to support heavy loads while maintaining a low friction coefficient, which enhances efficiency and reduces wear and tear over time.

The benefits of using V groove roller bearings extend far beyond mere load capacity. Their unique design provides enhanced stability and alignment during operation, making them a preferred choice for applications that require precision and reliability. Additionally, these bearings can easily adapt to different angles and orientations, which adds to their versatility across various industries. As global trade continues to evolve, understanding the trends and certifications associated with V groove roller bearings becomes crucial for manufacturers and consumers alike, ensuring compliance with international standards and optimizing performance across the board.

V Groove roller bearings have become essential components across various industries due to their unique design and functional benefits. These bearings are characterized by their V-shaped grooves that allow them to run smoothly on rails and provide precise guidance for sliding and rotating applications. In manufacturing and automation, for example, V Groove bearings facilitate the seamless movement of conveyors, enabling efficient material handling and reducing downtime in production processes.

In the woodworking industry, these bearings play a crucial role in guiding tools and machinery, ensuring accuracy in cutting and shaping materials. Their ability to withstand heavy loads and maintain stability makes them ideal for use in CNC machines and sliding table saws. Moreover, V Groove roller bearings are increasingly being integrated into robotics, where they support linear motion systems, providing the precision needed for tasks such as assembly and packaging. As companies focus on enhancing productivity and minimizing maintenance, the demand for high-quality V Groove roller bearings is set to rise, showcasing their significance in real-world applications across diverse sectors.

V Groove roller bearings are essential components in various applications, but they often encounter specific challenges that can affect performance. Common issues include misalignment, inadequate lubrication, and wear due to operational stresses. Misalignment can lead to uneven load distribution, causing excessive wear and potential failure. Solutions like precision installation and the use of adjustable mounts can mitigate these problems effectively.

Lubrication is another critical aspect; improper lubrication can increase friction and lead to overheating. Recent reports have highlighted that deep groove ball bearings, which share some principles with V Groove bearings, exhibit improved longevity and reduced noise levels when optimal lubrication strategies are implemented. According to industry data, effective lubrication can reduce friction by up to 30%, enhancing the overall service life of bearings.

Moreover, developments in bearing technology, such as the analysis of spiral groove bearing designs, indicate that innovative geometries can significantly improve performance under various load conditions. This ongoing research, including CFD studies on lubricant flow, points towards optimized bearing designs that can help resolve common issues faced in the application of V Groove roller bearings, ensuring they maintain their efficiency and reliability in demanding environments.

Global trade certifications have a significant impact on the quality and reliability of V groove roller bearings. These certifications ensure that manufacturers adhere to strict industry standards, which in turn translates to products that meet high-performance metrics. In a market where these bearings are critical components in applications ranging from automotive systems to heavy machinery, compliance with global standards enhances consumers' trust and value in the products they purchase.

With the rise of international trade, the importance of understanding certifications has grown. Customers increasingly seek bearings that not only fit their technical requirements but also come with verified quality assurances. The presence of recognized certifications can prevent the risks associated with subpar products, which can lead to failures and costly downtimes. As such, consumers are encouraged to consider the certification status of V groove roller bearings while procuring components, ensuring they invest in reliable and durable solutions for their needs.

In recent years, the V groove roller bearing market has seen significant technological advancements and evolving market demands. These bearings are increasingly utilized in automation applications, where precision and efficiency are critical. One prominent trend is the integration of smart technology, allowing for real-time monitoring of bearing performance. This innovation not only enhances productivity but also extends the service life of the bearings, reducing downtime and maintenance costs.

Moreover, the growing emphasis on sustainability has influenced the manufacturing processes of V groove roller bearings. Companies are now prioritizing eco-friendly materials and production techniques, responding to consumer demand for greener alternatives. This shift is not only beneficial for the environment but also aligns with global trade certifications that promote responsible sourcing and production practices. As the market continues to evolve, manufacturers that invest in these emerging technologies and sustainable practices are well-positioned to capture a larger share of the growing global demand for V groove roller bearings.

| Type | Material | Load Rating (kN) | Certification | Market Demand (Units/Year) | Emerging Trends |

|---|---|---|---|---|---|

| Deep Groove | Steel | 15 | ISO 9001 | 150000 | Self-lubricating |

| Angular Contact | Ceramic | 20 | DIN EN | 100000 | High-speed applications |

| Self-aligning | Stainless Steel | 12 | CE | 80000 | Eco-friendly manufacturing |

| Double Row | Plastic | 25 | RoHS | 50000 | Lightweight designs |