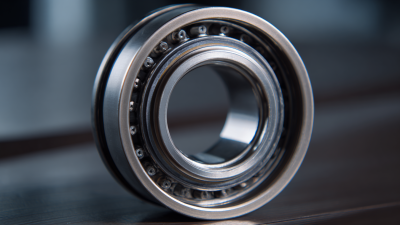

When it comes to ensuring the smooth operation of machinery in various industries, the significance of Tapered Roller Bearings cannot be overstated. These essential components are specifically designed to accommodate both radial and axial loads, making them a preferred choice in many global procurement strategies. In our comprehensive guide, we will delve into the myriad types of Tapered Roller Bearings available in the market, exploring their unique features and applications. Understanding the nuances of these bearings is crucial for procurement professionals looking to enhance their supply chain efficiency and machinery performance. Whether you are involved in automotive, aerospace, or heavy machinery sectors, this guide will equip you with the knowledge needed to source the most suitable tapered roller bearings for your operational needs. Join us as we unravel the complexities of these vital components and their sourcing strategies in a global context.

Tapered roller bearings are essential components in various machinery and automotive applications, playing a crucial role in reducing friction and supporting radial and axial loads. The global market for tapered roller bearings has seen significant growth, driven by advancements in manufacturing processes and the increasing demand from sectors like automotive, aerospace, and industrial machinery. As of 2023, the market is projected to expand at a compound annual growth rate (CAGR) of approximately 4.5%, indicating a robust demand for these components worldwide.

One of the key growth trends in the tapered roller bearing market is the shift towards automation and electric vehicles, which require high-performance bearings to withstand increased operational stresses. Furthermore, the ongoing development of smart technologies is pushing manufacturers to innovate and produce bearing solutions that enhance efficiency and durability. With the growing awareness of energy efficiency and sustainable practices, procurement strategies are evolving to favor suppliers who prioritize environmentally responsible production methods, ensuring that the future of tapered roller bearings is not only driven by performance but also by sustainability.

The global procurement of tapered roller bearings is significantly influenced by several key factors as the market continues to expand. With the global bearing market projected to reach a valuation of $46.82 billion by 2024 and anticipated to grow to $97.10 billion by 2032, the increasing demand for durable and efficient components is driving this surge. Industries such as automotive, aerospace, and heavy machinery are notably contributing to the uptrend as they seek advanced bearing solutions that enhance performance and reduce maintenance costs.

One of the primary drivers behind the global procurement of tapered roller bearings is technological advancement. Manufacturers are increasingly focusing on innovation, which involves developing bearings that can withstand higher loads and operate effectively in diverse environmental conditions. Furthermore, the rising trend of automation and robotics in various sectors is propelling the demand for high-quality bearings that can ensure uninterrupted operation and reliability. As companies look to optimize their supply chains, understanding these dynamics will play a crucial role in sourcing decisions and strategic procurement planning.

When sourcing high-quality tapered roller bearings, it is essential to establish a robust set of evaluation criteria that cater to specific procurement needs. Begin by assessing the manufacturer's reputation and experience in the industry. A company with a proven track record typically demonstrates reliability in product quality and customer service. Additionally, consider the production technologies employed, such as advanced manufacturing processes and quality control measures, which are crucial for ensuring the bearings meet rigorous performance standards.

Another vital aspect is the material quality used in production. High-grade materials enhance the durability and efficiency of tapered roller bearings, making them suitable for challenging applications in automotive and industrial sectors. Furthermore, compliance with international standards should be a priority, as it ensures that the bearings can withstand different operational stresses. Lastly, evaluate the supplier’s logistical capabilities, examining their ability to deliver products in a timely manner, especially in a global procurement landscape where delays can negatively impact operations. By focusing on these criteria, procurement professionals can make informed decisions that result in selecting the most reliable and high-quality tapered roller bearings.

When it comes to sourcing tapered roller bearings, understanding the key regions for manufacturing can significantly impact your procurement strategy. Major manufacturing hubs include Asia, particularly China and Japan, as well as European countries such as Germany and Italy. These regions are characterized by advanced production technologies and a robust supply chain network, ensuring quality and availability. Additionally, emerging markets in Southeast Asia are gaining traction, offering cost-effective solutions without compromising on standards.

**Tips for Sourcing:**

1. **Evaluate Manufacturer Credentials:** Always conduct thorough background checks on potential suppliers. Look for certifications and industry standards they adhere to, which can serve as indicators of reliability.

2. **Leverage Local Knowledge:** Engaging local procurement agents or consultants can provide invaluable insights into market dynamics and supplier capabilities that are not readily accessible online.

3. **Consider Future Trends:** Stay informed about market forecasts, especially in high-demand sectors like automotive and renewable energy, as these can influence supply availability and pricing. Understanding these trends can help you make more strategic sourcing decisions.

| Region | Manufacturing Capacity (Tons/Year) | Key Export Markets | Average Lead Time (Days) | Key Raw Materials |

|---|---|---|---|---|

| Asia | 500,000 | USA, Europe | 30 | Steel, Nylon |

| Europe | 300,000 | Asia, North America | 25 | Brass, Chrome |

| North America | 200,000 | Europe, South America | 20 | Steel, Bronze |

| South America | 100,000 | USA, Europe | 35 | Plastic, Steel |

| Africa | 50,000 | Europe, Asia | 40 | Iron, Stainless Steel |

When considering the sourcing strategies for tapered roller bearings, it’s essential to conduct a thorough cost analysis to ensure optimal procurement decisions. The global bearings market, valued at $46.82 billion in 2024, is witnessing robust growth, projected to reach $97.10 billion by 2035. This growth trajectory indicates an increasing demand for various types of bearings, including tapered roller bearings, which are vital components in numerous applications, particularly in the automotive and industrial sectors.

Different sourcing strategies can significantly impact the overall costs involved in procurement. For instance, sourcing directly from manufacturers might offer lower unit costs but could require larger order volumes and longer lead times. In contrast, partnering with local distributors might result in higher per-unit prices but can provide benefits like improved delivery times and better after-sales support. Analyzing these strategies helps organizations find a balance between cost-effectiveness and operational efficiency, ultimately ensuring that they meet the evolving demands of the market.