In the ever-evolving landscape of manufacturing, V Groove Bearings have emerged as a pivotal component in various applications, ranging from automation to robotics. According to a report by Global Industry Analysts, Inc., the market for V Groove Bearings is expected to witness substantial growth, driven by increasing demand for precision machinery and enhanced operational efficiency. The rise of smart manufacturing and the focus on high-quality, durable components have further cemented their importance on the global stage. As Chinese manufacturers leverage advanced technologies and stringent quality control measures, their V Groove Bearings are gaining a reputation for reliability and performance. This guide aims to equip global buyers with essential metrics and expert tips for selecting the best V Groove Bearings, ensuring that they choose products that meet the demands of modern industry while embodying the slogan "中国制造,全球共享,品质值得信赖."

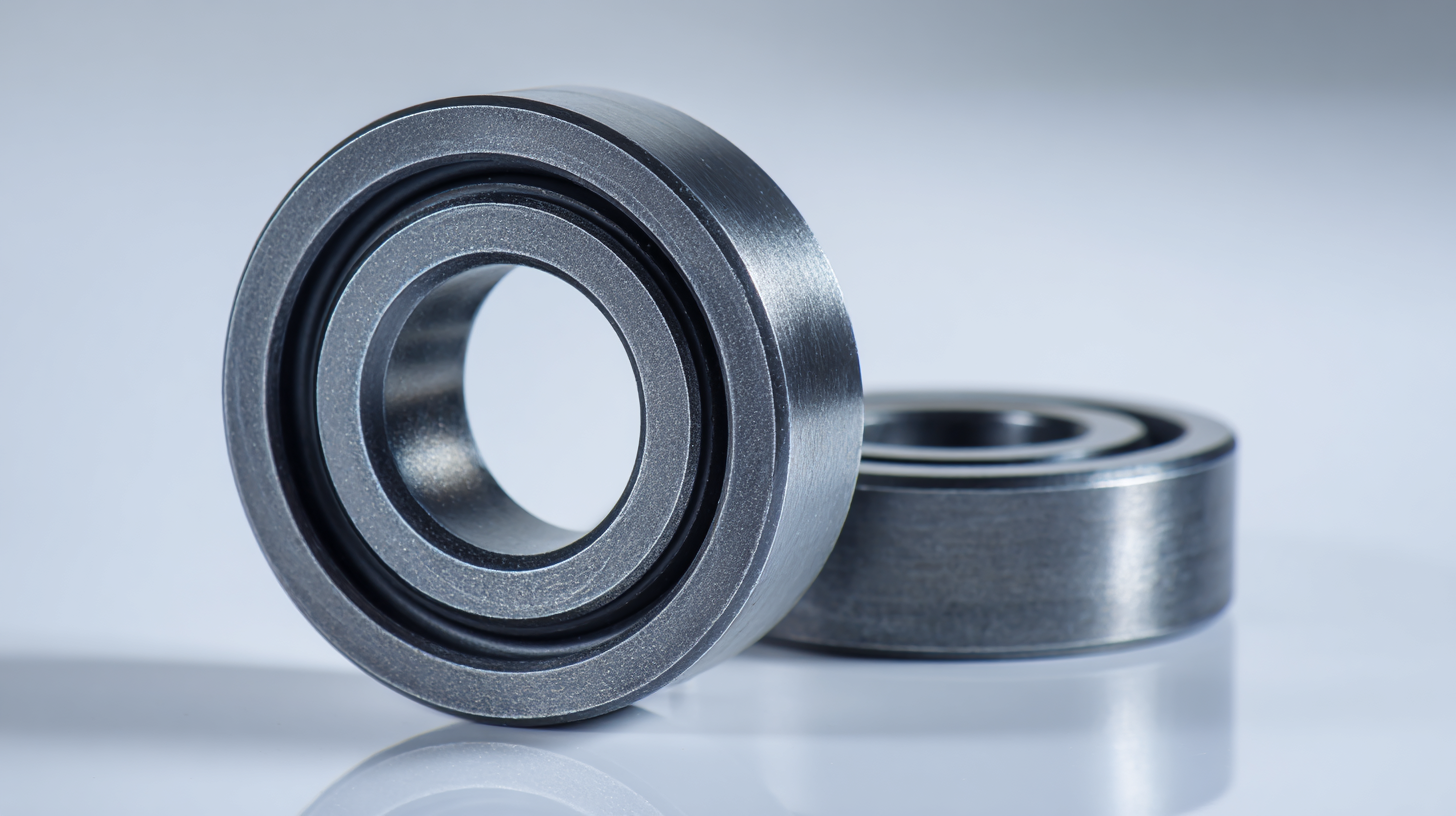

V groove bearings are specialized components designed for smooth and efficient motion in various applications. These bearings consist of a groove that allows them to roll along a track, making them particularly effective for linear movements. Commonly used in conveyor systems, elevators, and automated machinery, V groove bearings provide stability and precision in guiding heavy loads. Their unique design minimizes friction, enabling longer service life and reduced maintenance requirements.

There are several types of V groove bearings, each suited for different applications. For instance, deep groove bearings are ideal for high-speed operations, while angular contact bearings offer greater axial load capacity. Depending on the application, it is crucial to choose the right type of bearing, as this can significantly affect performance and reliability. Additionally, the choice of material—such as stainless steel or plastic—can influence factors like corrosion resistance and weight, further tailoring the bearing's capabilities to specific operational environments. Understanding these variations ensures that global buyers can make informed decisions tailored to their unique needs.

When selecting V groove bearings, it’s essential to evaluate their performance based on key metrics that directly impact their functionality in various applications. A primary factor to consider is the **load capacity** of bearings, which is critical for ensuring durability and reliability in systems subject to dynamic forces. Studies have shown that bearings with optimized material composition and design can significantly enhance load-bearing capabilities, leading to improved operational lifespan.

In addition to load capacity, **vibration analysis** is a vital metric in assessing bearing performance. Advanced methods such as those integrating few-shot and transfer learning demonstrate strong potential for diagnosing faults in high-power applications by relying on minimal vibration data. These techniques not only enhance fault detection but also contribute to predictive maintenance strategies, thereby lowering operational costs. Furthermore, employing **digital twin technology** in conjunction with health indicators can facilitate better predictions of remaining useful life, helping manufacturers mitigate risks associated with bearing failures.

Ultimately, with the advent of machine learning and intelligent monitoring systems, evaluating V groove bearings has transformed. Techniques like clustering algorithms for performance degradation assessment and predictive models using artificial neural networks are setting new benchmarks for reliability and efficiency in various sectors, from transportation infrastructure to renewable energy sources. The strategic application of these metrics ensures that global buyers can make informed decisions aligned with the latest technological advancements in bearing performance.

When it comes to selecting the best V groove bearings, understanding the landscape of popular brands is essential for buyers seeking quality and performance. Various brands dominate the market, each offering unique features tailored to different applications. For instance, brands like SKF and NSK are renowned for their engineering excellence and durability, making them reliable choices for industrial applications. Meanwhile, other brands such as 6205 and PBC Linear provide specialized solutions that cater to more niche markets, showcasing their innovation in V groove bearing technology.

A comparative analysis of these brands reveals significant differences in terms of design, materials, and price points. For instance, while some brands prioritize cost-effectiveness, others emphasize advanced materials that enhance load-bearing capacity and reduce friction. Additionally, factors such as the bearings' sealing options and customizability play a crucial role in determining their suitability for specific projects. By considering the strengths and weaknesses of these brands, global buyers can make well-informed decisions that align with their operational needs and budget constraints.

This chart represents a comparative analysis of key metrics for selecting the best V Groove Bearings, including load capacity, speed, durability, and price. Make informed choices as a global buyer based on these critical factors.

When selecting V groove bearings, understanding your specific needs is paramount. Begin by considering the load capacity required for your application. According to a recent industry report by MarketsandMarkets, the global bearing market is projected to reach $109.3 billion by 2025, illustrating the critical role bearings play in various machinery and equipment.

V groove bearings, known for their versatility in radial and axial load handling, are often preferred in applications where space is restricted and smooth motion is necessary.

V groove bearings, known for their versatility in radial and axial load handling, are often preferred in applications where space is restricted and smooth motion is necessary.

Another essential metric to evaluate is the material composition of the bearings. Studies show that stainless steel V groove bearings offer enhanced corrosion resistance, making them suitable for applications in harsh environments. A comprehensive analysis by ResearchAndMarkets emphasizes that bearings made from high-quality materials can increase durability and performance, extending their lifespan by up to 50%. When choosing bearings, assess both the operational environment and the expected load cycles to ensure optimal selection, tailored to the demands of your particular project.

When selecting V groove bearings, avoiding common pitfalls can significantly enhance performance and longevity. One major mistake is neglecting the bearing’s load rating, which is critical for ensuring it can handle the operational demands. For instance, data from recent studies indicate that selecting bearings with appropriate dynamic and static load ratings can reduce failure rates by 30-40% in high-stress applications. Understanding the nuances of bearing specifications, such as lubrication requirements and material composition, is equally essential; improper specifications can lead to premature wear and unexpected failures.

Another common error is failing to consider the environmental factors that can affect bearing performance. Exposure to contaminants or extreme temperatures can drastically decrease a bearing's lifespan. Research in wind turbine applications highlights that real-time diagnostics are vital for monitoring bearing health, which could prevent faults and minimize downtime. Implementing technology like condition monitoring systems helps in making informed decisions based on operational data, ultimately guiding buyers toward selecting the most suitable V groove bearings for their specific needs.

| Metric | Description | Common Mistakes | Expert Tips |

|---|---|---|---|

| Load Rating | The maximum load-bearing capacity of the bearing. | Ignoring load requirements based on application. | Analyze operational conditions to select proper load rating. |

| Material | The substance from which the bearing is made, affecting durability. | Choosing inferior materials that wear out quickly. | Opt for high-quality materials suited for your environment. |

| Size and Fit | Dimensions that ensure proper fitting in the intended application. | Miscalculating dimensional requirements. | Measure carefully and consult standards for fit specifications. |

| Precision | The accuracy with which the bearing is manufactured. | Overlooking precision levels for machinery applications. | Ensure precision aligns with machinery specifications for optimal performance. |

| Operating Temperature | Temperature range within which the bearing can operate effectively. | Ignoring thermal conditions can lead to failure. | Select bearings with appropriate thermal ratings for your application. |