In an era where the efficiency and reliability of machinery are paramount, understanding the functionality of bearing rollers has become increasingly critical. A recent industry report by the International Journal of Mechanical Engineering highlights that approximately 90% of rotating machinery failures are attributed to bearing-related issues, emphasizing the importance of these components. Bearing rollers, integral to the smooth operation of machinery, serve to reduce friction, support loads, and enhance the overall lifespan of equipment.

With global advancements in manufacturing and materials, the design and performance of bearing rollers have evolved, leading to significant improvements in energy efficiency and operating speeds. As industries strive for greater productivity and sustainability, a comprehensive understanding of bearing roller functionality is essential for engineers and maintenance professionals alike.

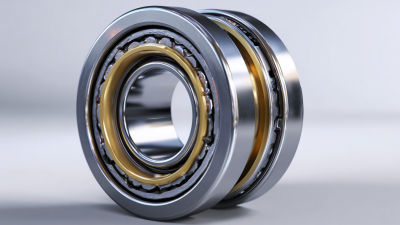

Bearing rollers play a crucial role in modern machinery, particularly in industrial applications where reliability and efficiency are paramount. These components, specifically designed to reduce friction and facilitate smooth motion, are vital in various systems, including automotive, where roller bearings are commonly used in wheel hubs and transmissions. According to industry analysts, the global automotive bearing market is projected to reach USD 60 billion by 2025, driven by the increasing demand for durable and high-performance parts. Roller bearings, known for their ability to handle heavy loads, are essential for ensuring the optimal performance of machinery.

Incorporating advanced technologies, such as triboelectric nanogenerators in cylindrical roller bearings, enhances their capabilities, allowing for energy harvesting and self-powered fault diagnostics. This innovation not only improves the efficiency of equipment but also supports proactive maintenance strategies. Regularly monitoring bearing health is crucial; effective condition monitoring can prevent costly downtimes and ensure operational safety.

**Tip**: Always ensure proper lubrication of bearing rollers to reduce wear and extend service life. This is particularly vital in high-speed and precision manufacturing settings where non-contact bearings are increasingly utilized. **Tip**: Consider integrating smart sensors for real-time monitoring of bearings, enabling timely interventions that can mitigate failure risks and maintain production efficiency.

| Bearing Type | Material | Load Capacity (kN) | Speed Limit (rpm) | Common Applications |

|---|---|---|---|---|

| Roller Bearing | Steel | 40 | 3000 | Heavy Machinery, Conveyors |

| Cylindrical Roller Bearing | Chromium Steel | 50 | 2500 | Electric Motors, Pumps |

| Tapered Roller Bearing | Alloy Steel | 70 | 1800 | Automotive, Gearboxes |

| Spherical Roller Bearing | Stainless Steel | 60 | 1500 | Wind Turbines, Construction Equipment |

| Needle Bearing | Carbon Steel | 30 | 5000 | Automotive, Appliance Motors |

Bearing rollers play a crucial role in modern machinery, with various types designed to meet specific operational requirements. Among these, tapered-roller bearings are notable for their use in freight railcar services, consisting of three fundamental components: rollers, inner rings (cones), and outer rings (cups). The design of tapered-roller bearings enables them to support both radial and axial loads, making them ideal for heavy-load applications. According to industry reports, these bearings can withstand loads exceeding 1,000 kN, which is essential in high-stress environments like rail transport where reliability is paramount.

Other types of bearing rollers, such as planetary roller screws, are designed to perform under extreme conditions, including high loads and precision requirements typical in aerospace applications. Studies reveal that the bearing characteristics of these systems must account for significant overload scenarios, often leading to innovative design modifications that enhance performance and longevity. Additionally, advancements in defect detection, such as the centroid growth selective clustering method, have improved the reliability of silicon nitride ceramic bearing rollers by addressing surface defects known to impact operational efficiency. This technology aids manufacturers in maintaining stringent quality control and prolonging the lifespan of these critical components.

The material composition of roller bearings plays a crucial role in determining their performance and longevity in modern machinery. Typically, roller bearings are made from high-carbon chromium steel due to its excellent hardness and wear resistance. This material allows bearings to withstand high loads and reduce friction, enhancing the overall efficiency of machinery. Additionally, advancements in lubrication technologies, such as the use of synthetic oils and greases, have enabled these bearings to function optimally under various temperature conditions, further extending their service life.

The material composition of roller bearings plays a crucial role in determining their performance and longevity in modern machinery. Typically, roller bearings are made from high-carbon chromium steel due to its excellent hardness and wear resistance. This material allows bearings to withstand high loads and reduce friction, enhancing the overall efficiency of machinery. Additionally, advancements in lubrication technologies, such as the use of synthetic oils and greases, have enabled these bearings to function optimally under various temperature conditions, further extending their service life.

Design considerations for roller bearings involve not only the selection of materials but also the geometry and surface treatment. The design must account for factors like internal clearance, rolling element profile, and raceway finish to minimize fatigue and enhance load distribution. Innovations such as the introduction of ceramic materials or hybrid bearings are emerging to increase resistance to corrosion and reduce weight. As machinery becomes increasingly specialized and demands greater precision and reliability, focusing on both material composition and design will be essential for the development of cutting-edge roller bearings in the industry.

Bearing rollers play a crucial role in ensuring the smooth operation of modern machinery, but they often face specific challenges that can compromise their performance. One common issue is inadequate lubrication, which can lead to increased friction and higher wear rates. When lubrication is insufficient, bearing rollers can overheat, causing potential failures. To mitigate this, it's essential to implement regular maintenance schedules that include checking and replenishing lubricant levels to ensure optimal performance.

Another significant challenge is contamination from external particles, which can introduce abrasive materials into the bearing assembly, leading to premature wear. To tackle this problem, manufacturers are increasingly using advanced seals and custom-designed enclosures that provide better protection against dirt and moisture. Additionally, regular cleaning and inspection procedures can help identify contamination before it causes serious damage. By addressing these challenges with proactive maintenance and innovative design solutions, the efficiency and longevity of bearing rollers can be greatly enhanced, ensuring that modern machinery continues to operate at peak performance.

The future of bearing roller technology is poised for significant advancements, driven by the continuous evolution of machinery demands. According to a report by MarketsandMarkets, the global bearing market is expected to reach USD 165.2 billion by 2026, with a notable emphasis on premium-quality bearing rollers due to their critical role in enhancing machine efficiency and longevity. Innovations in materials, such as the development of advanced composite and ceramic rollers, promise to not only reduce friction but also extend operational life, thereby minimizing maintenance costs.

For manufacturers looking to stay ahead in the competitive landscape, it is essential to embrace these emerging trends. Incorporating smart technologies, like IoT-enabled bearings, can offer real-time monitoring and predictive maintenance capabilities. This not only enhances operational reliability but also optimizes performance based on actual usage data, leading to informed decision-making.

Tips: When selecting bearing rollers for modern machinery, consider the environmental conditions they will face. For instance, opting for corrosion-resistant materials can significantly increase durability in harsh environments. Additionally, don't overlook the importance of proper lubrication; it can greatly affect the efficiency and lifespan of bearing rollers, especially in high-speed applications.