Cylindrical Roller Bearings (CRBs) are crucial components in a wide range of industrial applications, known for their ability to handle high radial loads and provide excellent performance in demanding environments. According to the March 2023 report by Technavio, the global bearing market is projected to grow by USD 33.57 billion from 2022 to 2026, with CRBs being a significant contributor due to their efficiency and reliability. However, to ensure their optimal performance and longevity, it's essential to implement best practices in maintenance and operation. This blog outlines five essential tips specifically designed to enhance the performance and extend the lifespan of Cylindrical Roller Bearings, drawing on industry insights and data to provide actionable solutions for manufacturers and engineers alike.

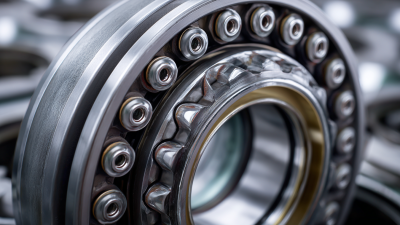

Cylindrical roller bearings are vital components in various industrial applications, and understanding their basics is crucial for effective maintenance. These bearings consist of cylindrical rollers that reduce friction between the rotating shaft and the stationary housing, allowing for improved efficiency and load capacity. Their design caters to both radial and axial loads, making them suitable for a wide range of machinery, from electric motors to heavy construction equipment.

Cylindrical roller bearings are vital components in various industrial applications, and understanding their basics is crucial for effective maintenance. These bearings consist of cylindrical rollers that reduce friction between the rotating shaft and the stationary housing, allowing for improved efficiency and load capacity. Their design caters to both radial and axial loads, making them suitable for a wide range of machinery, from electric motors to heavy construction equipment.

Proper maintenance of cylindrical roller bearings involves regular inspection and lubrication. It's essential to check for signs of wear, such as abnormal noise or vibration, which can indicate the need for replacement or repair. Additionally, utilizing the right type of lubricant is key, as it enhances performance and extends the bearing's lifespan. By comprehensively understanding these components' fundamentals, operators can implement best practices that ensure smoother operation and reduce downtime, ultimately leading to enhanced performance and longevity.

Cylindrical roller bearings are critical components in various industrial applications, offering high load-carrying capacity and operational reliability. Several key factors can significantly influence their performance and longevity. One of the most impactful elements is the bearing's lubrication. According to a report by SKF, proper lubrication reduces friction and wear, boosting the efficiency of bearings by up to 30%. In addition, the right lubricant can prevent overheating, extending the lifecycle of the bearings and ultimately reducing maintenance costs.

Another critical consideration is the alignment and installation of the bearings. Misalignment can lead to uneven stress distribution and premature failure. A study by Timken indicates that misaligned bearings could reduce bearing life by as much as 30%. Additionally, factors such as the quality of materials used in manufacturing and the operating environment—such as temperature and contamination levels—play vital roles in determining bearing performance. Implementing proper installation techniques and maintaining a clean operating environment can mitigate these issues, ensuring that cylindrical roller bearings operate efficiently, thereby enhancing their reliability and service life in demanding applications.

Effective lubrication is crucial for enhancing the life of cylindrical roller bearings. Proper lubrication minimizes friction, reduces wear, and protects against contaminants. One fundamental tip is to choose the right lubricant based on the operating conditions and the specific application. Synthetic lubricants often provide superior performance in extreme temperatures, whereas greases can offer better protection against moisture.

Regular maintenance and monitoring of lubrication levels are also essential. Over-lubrication can cause overheating and excessive pressure, while under-lubrication may lead to metal-to-metal contact, resulting in premature failure. Implementing a consistent lubrication schedule tailored to the bearing's operational demands will help ensure optimal performance.

Furthermore, utilizing modern lubrication techniques, such as automatic lubrication systems, can enhance efficiency. These systems deliver precise amounts of lubricant at regular intervals, ensuring that the bearings receive adequate lubrication without manual intervention. By applying these effective lubrication techniques, businesses can significantly boost the performance and longevity of their cylindrical roller bearings.

| Tip | Description | Benefits | Recommended Lubricants |

|---|---|---|---|

| Regular Lubrication | Apply lubricant at specified intervals to maintain a thin protective film. | Reduces friction and wear, prolongs bearing life. | Synthetic Oils, Lithium Grease |

| Proper Viscosity | Choose lubricants with the right viscosity for operating conditions. | Ensures optimal film thickness; lowers risk of overheating. | Multi-Grade Oils |

| Cleanliness | Keep the bearing area free of contaminants. | Prevents premature failure due to debris. | High-Purity Oils, Filtering Systems |

| Operating Temperature | Monitor and manage the temperature of bearings. | Helps maintain lubricating properties; prevents oxidation. | Thermal Oils |

| Condition Monitoring | Use sensors to monitor bearing condition and lubrication effectiveness. | Early detection of issues; enhances maintenance planning. | Condition Monitoring Systems |

When it comes to maximizing the performance and longevity of cylindrical roller bearings, proper installation is crucial. According to a report by the International Council on Machinery Lubrication, improper installation can lead to premature failure in up to 30% of bearing applications. To avoid these common mistakes, it’s essential to follow best practices.

One major installation mistake is using excessive force during the fitting process. This can cause brinelling—a form of surface damage that affects the roller's performance. Instead, ensure a smooth and correct assembly by using appropriate tools and techniques, allowing for a controlled fit. Additionally, maintaining the correct alignment is vital; misalignment can lead to uneven wear and can reduce bearing life significantly.

One major installation mistake is using excessive force during the fitting process. This can cause brinelling—a form of surface damage that affects the roller's performance. Instead, ensure a smooth and correct assembly by using appropriate tools and techniques, allowing for a controlled fit. Additionally, maintaining the correct alignment is vital; misalignment can lead to uneven wear and can reduce bearing life significantly.

Furthermore, neglecting to check cleanliness can also result in contamination. Particulate matter entering the assembly can lead to operational hazards and reduced efficiency. Therefore, prior to installation, always inspect and clean the bearing and surrounding components thoroughly. Implementing these tips will not only enhance the performance of cylindrical roller bearings but also extend their operational longevity.

Regular maintenance practices are crucial for ensuring the optimal functionality of cylindrical roller bearings. One essential tip is to conduct routine inspections. Regularly check for signs of wear or damage, and listen for unusual noises during operation. Early detection of issues can prevent costly downtime and extend the lifespan of your bearings.

Another important aspect is maintaining proper lubrication. Ensuring that your bearings are adequately lubricated reduces friction and wear, which can lead to overheating and failure. Use the recommended type and amount of lubricant, and consider implementing a lubrication schedule based on operating conditions. This proactive approach will help keep your bearings performing smoothly.

Lastly, monitor operating temperatures. Elevated temperatures can indicate underlying problems or inadequate lubrication. By incorporating temperature monitoring into your maintenance routine, you can address potential issues before they escalate. This practice not only enhances the performance of your cylindrical roller bearings but also contributes to their longevity, ensuring they operate efficiently for years to come.