In the ever-evolving landscape of modern industries, the choice of machinery components can significantly impact efficiency and performance. Among these components, U Groove Roller Bearings stand out as an essential element for various applications. These innovative bearings provide a unique groove design that allows for smoother motion and better load distribution, making them ideal for a range of industrial settings. In this blog, we will explore seven essential benefits of U Groove Roller Bearings that highlight their versatility, durability, and cost-effectiveness. Whether you're in manufacturing, robotics, or automotive sectors, understanding these advantages will help you appreciate why U Groove Roller Bearings are a critical component in achieving operational excellence and sustaining competitive advantage in today's fast-paced industrial environment.

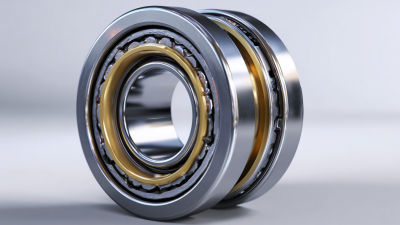

U Groove roller bearings play a pivotal role in modern manufacturing by significantly enhancing machinery efficiency. These specialized bearings are designed to accommodate radial and axial loads, making them an ideal choice for various applications within automated and heavy-duty equipment. Their unique U-shaped design not only facilitates smooth movement along the track but also reduces friction, which leads to lower energy consumption and extended equipment lifespan. As industries strive for greater efficiency and sustainability, the adoption of U Groove roller bearings is on the rise.

The impact of U Groove roller bearings is further underscored by the growing demands in the global bearings market, projected to climb to USD 97.10 billion by 2028. Significant growth in sectors such as automotive manufacturing—driven by advancements in technology and increasing vehicle fleets—highlights the necessity for high-performance components like U Groove roller bearings. By ensuring optimal performance and reliability in machinery, these bearings contribute to enhanced productivity and lower maintenance costs, ultimately driving industrial growth and innovation in the years to come.

U groove roller bearings are becoming increasingly popular in modern industries due to their ability to enhance load distribution and ultimately reduce costs. By allowing for even weight distribution across the bearing's surface, these innovative components help to minimize wear and tear on machinery. This improved distribution not only extends the lifespan of the bearings but also reduces the frequency of maintenance and replacements, leading to considerable cost savings over time.

Moreover, U groove roller bearings facilitate smoother operations, which can translate into added efficiency in production processes. When equipment operates more seamlessly, it reduces energy consumption and operational downtime, further contributing to economic benefits for industries. With manufacturers always on the lookout for ways to optimize performance while keeping expenses in check, the adoption of U groove roller bearings represents a strategic move towards achieving both reliability and cost-effectiveness in various applications.

U Groove roller bearings are gaining traction in modern industries due to their remarkable durability and longevity, which significantly impact maintenance costs. In a recent industry report by the Roller Bearing Manufacturer's Association, it was revealed that bearings with improved materials can reduce failure rates by up to 30%. U Groove bearings, crafted with high-quality steel and advanced coatings, not only extend the lifespan of machinery but also provide reliable performance under varying loads and speeds. This translates into lower maintenance and replacement costs for manufacturers.

To maximize the benefits of U Groove roller bearings, consider implementing regular maintenance schedules that include vibration analysis and lubrication checks. Research indicates that proper maintenance can further extend the lifespan of these bearings by another 25%. Additionally, investing in training for maintenance staff on the specifics of these bearings can lead to early detection of potential issues, thereby reducing unexpected downtimes.

When selecting U Groove roller bearings, it’s crucial to choose the right size and load ratings for your specific applications. According to a study from the International Journal of Engineering Research, using appropriately sized bearings can enhance efficiency by 20%, consequently lowering energy consumption. By integrating these best practices, industries can ensure that their U Groove roller bearings function optimally, resulting in significant cost savings and improved operational efficiency.

In the rapidly evolving field of robotics, precision and speed are paramount. U groove roller bearings have emerged as a crucial component in enhancing these performance metrics. According to a report by Research and Markets, the global robotics market is expected to grow to $210 billion by 2025, with increasing demand for efficient components that can improve operational capabilities. U groove roller bearings play a significant role in this development by reducing friction and allowing for smoother motion, thus directly influencing the speed and accuracy of robotic systems.

The engineering prowess of U groove roller bearings not only minimizes wear and tear but also supports higher load capacities, which is essential for modern industrial applications. For instance, a study from the International Journal of Advanced Manufacturing Technology indicates that the use of high-quality roller bearings can increase the lifespan of machinery by up to 30%. This longevity leads to lower maintenance costs and reduced downtime, which is critical for organizations striving for productivity in automated environments. As industries continue to innovate, U groove roller bearings stand out as a vital element in achieving exceptional performance in robotics and beyond.

| Benefit | Description | Impact on Robotics |

|---|---|---|

| Enhanced Precision | U groove design reduces friction and maintains alignment. | Improves cut accuracy in robotic arms. |

| Increased Speed | Allows for faster rotational movement without overheating. | Enhances operational speed of mobile robots. |

| Low Noise Operation | Designed to minimize operational noise levels. | Ideal for use in environments where noise reduction is critical. |

| Durability | Made from high-strength materials that resist wear. | Reduces maintenance costs and increases uptime. |

| Versatile Applications | Suitable for various robotic configurations. | Supports innovative designs in automation. |

| Improved Load Distribution | Distributes loads evenly to prevent point stress. | Enhances stability and reliability of robotic mechanisms. |

| Reduced Maintenance | Longer life span minimizes the need for frequent servicing. | Maximizes the productivity of robotic systems. |

In today’s rapidly evolving industrial landscape, U Groove roller bearings are gaining prominence as a superior alternative to traditional bearings. One of the primary distinctions lies in their unique design, which allows for smooth movement along tracks and guides. This feature minimizes friction and wear, resulting in enhanced efficiency and longer service life. Unlike conventional bearings that may struggle with misalignment, U Groove bearings excel in applications where precision and stability are critical, providing consistent performance under varying load conditions.

Moreover, the comparative analysis reveals significant weight savings with U Groove roller bearings, making them an ideal choice for industries focused on reducing energy consumption and improving overall performance. Their lightweight construction does not compromise strength; rather, it supports easier installation and maintenance. This advantage is particularly evident in high-speed applications, where traditional bearings may induce additional resistance. As industries continue to innovate, the adaptability and reliability of U Groove roller bearings could redefine operational standards, highlighting their role as a crucial component in modern machinery.