Cylindrical Roller Bearings play a pivotal role in the functioning and longevity of modern machinery. These bearings are critical components designed to support radial loads while allowing for limited axial displacement, thus enhancing operational efficiency and reliability. In various industrial applications—from automotive engines to heavy machinery—Cylindrical Roller Bearings facilitate smooth movement and minimize wear under extreme conditions.

Understanding the performance metrics associated with these bearings is vital for engineers and technicians, as it informs equipment maintenance and design optimizations. This introduction provides a comprehensive look into the types, key functions, and performance indicators of Cylindrical Roller Bearings, highlighting their indispensable contribution to mechanical systems and their impact on productivity in contemporary manufacturing and engineering domains.

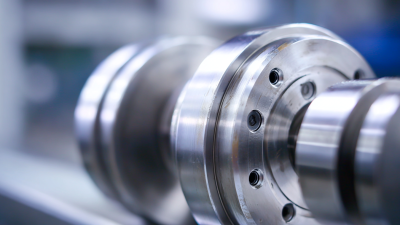

Cylindrical roller bearings are critical components in modern machinery, distinguished by their design, which allows for high load-carrying capacity and reduced friction. The fundamental structure of these bearings comprises a series of cylindrical rollers that are positioned between an inner and outer raceway. This configuration enables them to accommodate both radial and axial loads, making them ideal for applications where high performance and durability are essential. The rollers are typically arranged in a way that minimizes contact stress and enhances overall stability, contributing significantly to the efficiency of machinery.

The design features of cylindrical roller bearings include elements such as the improved surface finish of the raceways and the utilization of advanced materials that enhance their fatigue resistance. Additionally, the internal geometry can be optimized to provide better lubrication flow, reducing wear and extending service life. These characteristics not only improve the load distribution but also allow for higher speeds in applications such as electric motors and gearboxes, where precise performance is paramount. Understanding these design principles is essential for engineers seeking to maximize the performance of their machinery through the effective selection and application of cylindrical roller bearings.

Cylindrical roller bearings play a crucial role in the efficiency and reliability of modern machinery. Understanding the key performance metrics is essential for evaluating their capabilities and ensuring optimal operation in various industrial applications. Some of the most critical metrics include load capacity, speed ratings, and friction coefficients. These aspects determine how well a bearing can perform under different operational conditions, influencing both the longevity of the bearing and the overall machinery it supports.

When assessing cylindrical roller bearings, consider the following tips: First, always review the manufacturer's specifications for load ratings; this ensures that the bearings can handle the anticipated loads. Second, pay attention to the speed ratings; high-speed applications require bearings designed for greater rotational speeds to prevent overheating and premature failure. Lastly, evaluate the friction coefficients, as lower friction leads to improved efficiency and reduced energy consumption in machinery.

By focusing on these performance metrics, engineers and maintenance teams can make informed decisions when selecting cylindrical roller bearings for their specific applications, thereby enhancing the durability and performance of their machinery.

| Metric | Description | Typical Value |

|---|---|---|

| Load Capacity | Maximum load that the bearing can support | 5,000 - 100,000 N |

| Speed Rating | Maximum operating speed of the bearing | 1,000 - 10,000 RPM |

| Operating Temperature | Temperature range in which the bearing can operate efficiently | -30°C to +120°C |

| Vibration Level | Amount of vibration generated during operation | < 2 mm/s |

| Lubrication Type | Type of lubrication used for optimal performance | Grease/Oil |

| Life Expectancy | Expected operational life of the bearing | 10,000 - 50,000 hours |

Cylindrical roller bearings are vital components in a variety of industries, providing essential support for machinery that operates under heavy loads. These bearings excel in applications such as construction equipment, where high radial loads and demanding operating conditions are commonplace. Their ability to maintain stability and reduce friction makes them ideal for rotating equipment in manufacturing processes as well. This reliability ensures that machinery can operate smoothly, improving overall efficiency.

Cylindrical roller bearings are vital components in a variety of industries, providing essential support for machinery that operates under heavy loads. These bearings excel in applications such as construction equipment, where high radial loads and demanding operating conditions are commonplace. Their ability to maintain stability and reduce friction makes them ideal for rotating equipment in manufacturing processes as well. This reliability ensures that machinery can operate smoothly, improving overall efficiency.

When selecting cylindrical roller bearings, it's crucial to consider several performance metrics, such as load capacity, speed rating, and temperature resistance. Tip: Always consult with manufacturers to ensure that the bearings meet the specific operational requirements of your machinery. This helps to prevent premature wear and enhances the lifespan of the equipment. Additionally, proper lubrication and regular maintenance play a critical role in maximizing bearing performance and preventing downtime.

In industries like automotive and aerospace, cylindrical roller bearings are employed in applications ranging from gearboxes to turbine engines. Their versatility and robustness allow them to perform under high-stress conditions while maintaining precision. Tip: Keep an eye on vibration levels and temperature fluctuations in machinery, as these can indicate bearing health issues early on, allowing for timely interventions and reducing costly repairs.

Effective maintenance practices are crucial for maximizing the lifespan and performance of cylindrical roller bearings in modern machinery. Regular inspections and preventive maintenance can identify potential issues before they escalate, ensuring optimal operation and reducing costly downtimes. Incorporating condition-based maintenance strategies allows operators to monitor bearing health through vibration analysis and other diagnostic tools, enhancing reliability and extending operational life.

Utilizing the right lubrication is fundamental in bearing maintenance. Industrial greases are available in various formulations that cater to specific applications, ensuring efficient lubrication while protecting against wear and contaminants. Additionally, maintaining a clean environment around machinery reduces the risk of particles contaminating rolling bearings, which can lead to premature failure. By adopting these maintenance practices, machinery operators can enhance the durability and efficiency of their equipment, safeguarding their investments for the long term.

As industries continue to evolve, cylindrical roller bearings are at the forefront of technological advancements. Innovations such as optimized materials and enhanced manufacturing processes have led to improved performance and increased service life. The future of cylindrical roller bearing technology is expected to prioritize lightweight materials that can withstand higher loads while minimizing energy loss. This pivot is not only crucial for improving efficiency but also for reducing the environmental impact of machinery.

Moreover, digitalization and smart technology are transforming cylindrical roller bearings into intelligent components. The integration of sensors into bearing designs will enable real-time monitoring of performance metrics, such as temperature, vibration, and load conditions. This data-driven approach will allow for predictive maintenance, reducing downtime and enhancing overall operational efficiency. As industries strive for higher precision and reliability, the future of cylindrical roller bearing innovation is set to redefine performance standards across various sectors.