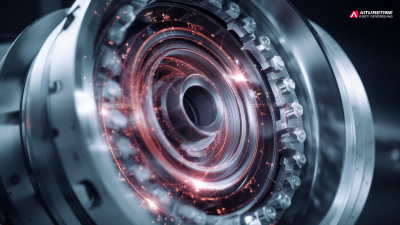

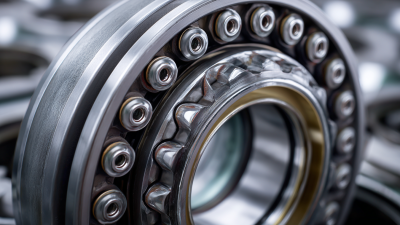

Cylindrical Roller Bearings (CRBs) play a crucial role in the performance and reliability of modern machinery, as they are engineered to handle heavy radial loads while maintaining high speeds and precision.

According to a recent report by the Research and Markets, the global market for bearings is expected to reach approximately $200 billion by 2027, with cylindrical roller bearings projected to account for a significant share due to their widespread applications in sectors such as automotive, aerospace, and manufacturing.

These bearings' unique design, featuring a series of cylindrical rollers, allows for improved load distribution and reduced friction compared to traditional designs.

As industries continue to evolve with the implementation of advanced technologies and automation, an in-depth understanding of cylindrical roller bearings becomes essential for engineers and manufacturers aiming to enhance the efficiency and durability of their mechanical systems.

Cylindrical roller bearings are crucial components in modern machinery, particularly in industrial applications where their unique features significantly enhance operational efficiency. These bearings are designed to support radial loads while allowing for some axial movement, making them ideal for heavy-duty applications. Their key characteristics include a high load capacity, minimal frictional losses, and durability under various operating conditions. This makes cylindrical roller bearings a preferred choice in sectors ranging from manufacturing to aerospace.

Cylindrical roller bearings are crucial components in modern machinery, particularly in industrial applications where their unique features significantly enhance operational efficiency. These bearings are designed to support radial loads while allowing for some axial movement, making them ideal for heavy-duty applications. Their key characteristics include a high load capacity, minimal frictional losses, and durability under various operating conditions. This makes cylindrical roller bearings a preferred choice in sectors ranging from manufacturing to aerospace.

Tips for Optimal Performance: To further maximize the performance of cylindrical roller bearings, consider implementing regular maintenance checks to monitor wear and tear. Additionally, using lubricants specifically designed for rolling element bearings can reduce friction, thereby extending bearing life. Lastly, pay attention to alignment during installation to prevent unnecessary stresses on the bearings.

With the increasing demand for reliability in machinery, especially in high-stakes environments like wind turbines, understanding the tribological performance of cylindrical roller bearings—specifically their inner raceway micro-textures—becomes essential. Research indicates that optimizing these micro-textures can enhance load distribution and reduce energy losses, presenting a critical area for further exploration in both academic and industrial contexts.

Cylindrical roller bearings play a vital role in modern machinery, particularly in their capacity to support radial loads. The ability to effectively handle high radial loads contributes significantly to machinery performance, enhancing efficiency and reliability. These bearings are designed to reduce friction and wear, ultimately leading to better energy consumption. As industries move toward eco-friendly practices, innovations such as sustainable greases, derived from materials like jojoba oil and plant waste, are being explored to further improve the performance of these bearings. Such advancements not only alleviate environmental concerns but also enhance the overall lifespan of the components.

Incorporating intelligent technologies into the analysis of bearing performance can revolutionize radial load support systems. For instance, applying machine learning techniques in data clustering can assist in predicting load patterns and energy consumption effectively. By understanding the complex interactions between machinery and its components, such as bearings, manufacturers can optimize design and materials, leading to enhanced performance under varying operating conditions. As the research community continues to innovate, the integration of advanced materials and predictive modeling will undoubtedly bolster the efficacy of cylindrical roller bearings in supporting radial loads and, by extension, machinery performance.

| Parameter | Description | Impact on Machinery Performance |

|---|---|---|

| Radial Load Capacity | Maximum radial load that the bearing can support | Ensures stability and minimizes deformation under load |

| Friction | Resistance to rolling or sliding motion | Lower friction improves energy efficiency and reduces heat generation |

| Load Distribution | How load is shared among rollers and raceways | Improved load distribution enhances durability and lifespan |

| Lubrication | Type and quality of lubricant used | High-quality lubrication decreases wear and improves performance |

| Operating Speed | Maximum speed at which the bearing can operate | Higher speeds increase efficiency but require optimized design |

Cylindrical roller bearings (CRBs) are gaining traction in modern machinery due to their unique advantages over other bearing types. According to a report by the Global Bearing Market, the demand for CRBs is expected to grow at a CAGR of 5.2% from 2022 to 2027. This growth is largely driven by their optimal load-carrying capacity and ability to handle high speeds, which is essential in applications ranging from automotive to industrial equipment. Compared to ball bearings, CRBs provide a larger contact area, which translates to better force distribution and decreased wear in heavy-load scenarios.

When juxtaposed with tapered roller bearings, CRBs stand out for their simplicity and ease of installation. Tapered roller bearings are often more complex, requiring careful alignment and maintenance. Statistically, cylindrical roller bearings can outperform in terms of operational life—research indicates that they can last up to 30% longer under similar load conditions. Furthermore, CRBs typically require less lubrication, making them a cost-effective choice for manufacturers looking to reduce overall operating expenses. This comparative advantage solidifies CRBs as a preferred choice for many engineers seeking reliable performance in demanding environments.

When designing and selecting cylindrical roller bearings, several critical factors must be considered to ensure optimal performance in modern machinery.

The load conditions, for instance, are paramount; these bearings must withstand various loads and motions. The direction and magnitude of loads can significantly impact the bearing's lifespan and functionality, making it essential to assess the application requirements carefully.

When designing and selecting cylindrical roller bearings, several critical factors must be considered to ensure optimal performance in modern machinery.

The load conditions, for instance, are paramount; these bearings must withstand various loads and motions. The direction and magnitude of loads can significantly impact the bearing's lifespan and functionality, making it essential to assess the application requirements carefully.

Another vital factor is the operating environment. Conditions such as temperature, humidity, and the presence of contaminants can affect the bearing material and lubrication choices.

For instance, high temperatures may necessitate specialized materials that can resist thermal deformation, while harsh environments may require seals or protective coatings to prevent contamination.

Additionally, the choice of lubrication—whether grease or oil—also influences the bearing's efficiency and durability, further complicating the selection process.

Finally, the dimensions and tolerances play a crucial role in the selection of cylindrical roller bearings. Precision in the design ensures that the bearing fits perfectly within the machinery, reducing friction and wear.

Engineers must carefully evaluate these factors to ensure that the bearings chosen not only meet the mechanical requirements but also enhance the overall reliability and efficiency of the equipment in which they are used.

Proper maintenance of cylindrical roller bearings is crucial for ensuring their longevity and optimal performance in modern machinery. Regular inspection and lubrication are key aspects of maintaining these components. It's important to utilize the correct type of lubricant, tailored to the operating conditions, and to apply it at appropriate intervals to prevent wear and overheating.

**Tips for Maintenance:**

1. **Routine Inspections:** Conduct regular checks for signs of wear or damage. Look for unusual noises or vibrations, which can indicate misalignment or lubrication issues. Identifying these problems early can help prevent more severe damage.

2. **Temperature Monitoring:** Keep an eye on the temperature of the bearings during operation. Excessive heat can be a sign of inadequate lubrication or contamination. Use thermal imaging or temperature sensors to regularly monitor temperatures and address any anomalies promptly.

3. **Cleanliness is Key:** Ensure that bearings are kept clean to prevent contamination by dirt and debris. Use appropriate cleaning methods and materials when handling the bearings, and maintain a tidy environment in the machinery workspace.

By following these best practices, manufacturers can significantly extend the operational life of cylindrical roller bearings, minimizing downtime and maintenance costs.

This bar chart illustrates the performance indicators of cylindrical roller bearings, highlighting their load carrying capacity, speed capability, durability, friction levels, and maintenance frequency. By understanding these core functions, we can establish best practices for maintaining roller bearings and maximizing their longevity.