In the world of industrial machinery and automotive applications, selecting the right components is crucial for performance and longevity. Particularly, Tapered Roller Bearings play a significant role in ensuring smooth operation under heavy loads while accommodating various axial and radial forces. According to industry expert Dr. Emily Harper, a renowned engineer in bearing technology, "Choosing the right Tapered Roller Bearing is not just about specifications; it’s about understanding the unique demands of your application."

This insight highlights the importance of tailoring your choice to meet specific operational requirements. As industries evolve and machinery becomes more advanced, the need for precision in bearing selection has never been more critical. Whether it's for a high-speed spindle, a robust axle assembly, or any application requiring precision performance, the right Tapered Roller Bearing can make all the difference.

In the following sections, we will explore the top insights for 2025, guiding you through the key considerations necessary for selecting the best Tapered Roller Bearings to meet your operational needs, ensuring not only efficiency but also reliability for years to come.

Tapered roller bearings are designed to accommodate both radial and axial loads, making them a versatile solution in various applications. Their unique tapered shape allows for an efficient load distribution along the bearing's surface, which significantly reduces friction and enhances performance. This design makes tapered roller bearings particularly well-suited for heavy-duty applications, including automotive and industrial machinery, where both stability and durability are paramount.

When selecting tapered roller bearings, it's crucial to consider specific factors such as load capacity, speed rating, and the type of environment in which they will operate. Bearings exposed to high temperatures or contaminants may require specialized materials or sealing options to ensure longevity. Additionally, the installation process must be conducted with precision to avoid premature wear or failure.

Tips: Always check manufacturer specifications carefully and choose the appropriate size based on the expected load. Regular maintenance, including lubrication and inspection, can greatly extend the lifespan of tapered roller bearings. Furthermore, ensure that the housing and shaft fit are optimal to eliminate unnecessary play, which could lead to operational inefficiencies.

| Specification | Details | Material | Load Capacity (kg) | Application |

|---|---|---|---|---|

| Metric Series 30220 | Tapered roller bearing for radial and axial loads | Chrome Steel | 1800 | Automotive industry |

| Imperial Series 25580 | Heavy-duty tapered roller bearing | Alloy Steel | 2500 | Industrial machinery |

| Metric Series 32310 | Standard tapered roller bearing for moderate loads | Chrome Steel | 950 | Agricultural equipment |

| Imperial Series 14130 | Light-duty tapered roller bearing | Carbon Steel | 1100 | Bicycle manufacturing |

| Metric Series 32007 | Compact tapered roller bearing | Stainless Steel | 1200 | Electrical motors |

When selecting tapered roller bearings, several key factors must be considered to ensure optimal performance and longevity. First, load capacity is crucial. It is important to match the bearing's load ratings with the operational requirements of your machinery. An understanding of both dynamic and static load capacities can help in choosing a bearing that will adequately support the expected loads without premature failure.

Another vital aspect is the bearing's material and design. Tapered roller bearings come in various materials that offer different levels of strength, corrosion resistance, and thermal stability. Factors such as operating environment, presence of contaminants, and temperature variations should guide the selection of the ideal material. Additionally, considerations regarding the geometry of the bearing – including the angle of the roller and raceway curvature – play a significant role in the bearing's efficiency and performance under different load conditions. Ensuring proper fit and alignment during installation is also essential to maximizing the lifespan and functionality of the tapered roller bearings.

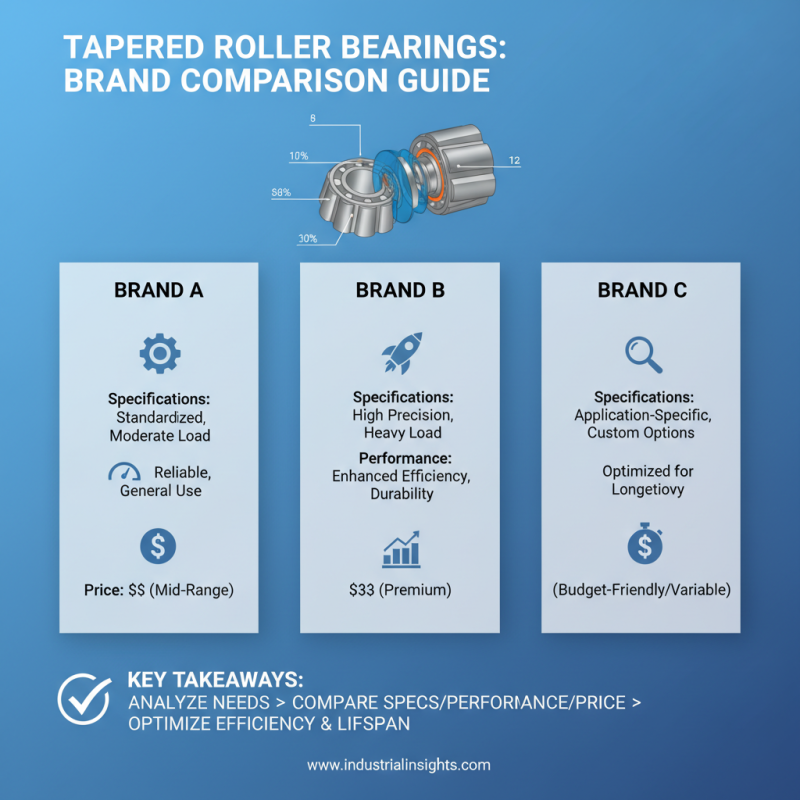

When selecting tapered roller bearings, it's crucial to understand the comparative aspects of various brands available in the market. Different brands may offer unique specifications, performance characteristics, and price ranges, making it essential to analyze these factors based on your specific application needs. A thorough comparison can reveal which bearings will provide optimal efficiency and longevity for your machinery or equipment.

**Tips:** One important consideration is the load capacity of the tapered roller bearings. Ensure that the bearing you select is capable of handling the maximum expected load in your application. Additionally, pay attention to the bearing's material composition and sealing options, as these components can significantly influence durability and resistance to contaminants.

Another aspect to examine is the availability of technical support and documentation from the manufacturer. Brands that provide comprehensive resources can facilitate better maintenance and troubleshooting. Researching user reviews or seeking recommendations can also help in identifying reliable options. Always keep in mind that investing time into understanding the attributes of different bearing brands will lead to a more informed purchasing decision, ultimately enhancing operational performance.

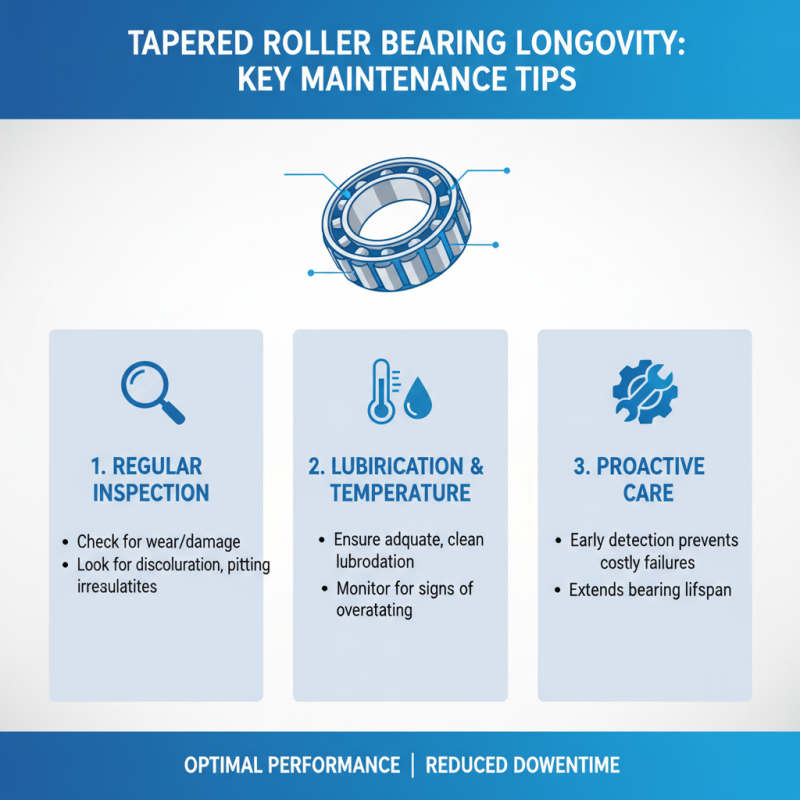

Maintaining the longevity of tapered roller bearings is essential for ensuring optimal performance in various applications. One of the key maintenance tips is to regularly inspect the bearings for signs of wear or damage. This includes checking for any discoloration, pitting, or surface irregularities that might indicate overheating or inadequate lubrication. Early detection of these issues can help prevent costly failures and extend the overall lifespan of the bearings.

Proper lubrication is another critical factor in maintaining tapered roller bearings. It is vital to use the right type of lubricant specifically designed for your operational conditions. Ensuring that the bearings are neither over-lubricated nor under-lubricated is essential; both conditions can lead to premature failure. Additionally, regular lubrication schedules should be established to maintain optimal performance, taking into consideration factors such as speed, load, and environmental conditions.

Finally, keeping the surrounding environment clean and free from contaminants is crucial for the longevity of tapered roller bearings. Dust, dirt, and moisture can compromise the bearings' performance and lead to premature wear. Implementing effective sealing solutions and establishing a routine cleaning schedule can significantly enhance the operational life of the bearings, ensuring they operate efficiently and reliably in their intended applications.

The landscape of tapered roller bearing technology is evolving rapidly, with significant innovations aimed at enhancing performance and reliability. In 2025, the integration of advanced materials and design methodologies is paving the way for bearings that can withstand higher loads and reduce friction significantly. According to a recent report by the International Bearing Association, advancements in lubrication technology and improved seal designs are projected to increase bearing life by up to 30%. This highlights the urgent need for industries to stay abreast of these developments to optimize their operations.

To select the best tapered roller bearings for your needs, it's essential to consider the latest innovations in performance metrics. New computational tools and online bearing selection software allow engineers to simulate load conditions more accurately than ever before. These tools can help users make informed decisions regarding load capacity, temperature ranges, and environmental factors.

**Tips:** Always consult up-to-date specifications and performance data when evaluating bearing options. Additionally, ensure that you factor in potential future demands when selecting bearings, as the right choice today can lead to substantial cost savings and increased operational efficiency down the line. Engage in regular training sessions to familiarize your team with new technologies to maintain your competitive edge in the market.

This bar chart illustrates the advancements in key attributes of tapered roller bearings expected in 2025. The dimensions considered include Load Capacity, Durability, Cost Efficiency, and Noise Reduction.