In the ever-evolving landscape of industrial applications, the selection of the right components is crucial for optimizing performance and ensuring longevity.

Groove Ball Bearings, which account for a significant percentage of bearing-related failures, play a pivotal role in machinery efficiency and reliability. According to a recent study by the International Organization for Standardization (ISO), approximately 30% of equipment downtime is attributed to bearing issues, underscoring the importance of making informed choices when it comes to these critical components.

With various alternatives available, including angular contact and self-aligning ball bearings, understanding the unique requirements of your application is essential. This blog will explore the different types of Groove Ball Bearings, highlighting key considerations and best practices to ensure that you select the most suitable option for your industrial needs.

Groove Ball Bearings, which account for a significant percentage of bearing-related failures, play a pivotal role in machinery efficiency and reliability. According to a recent study by the International Organization for Standardization (ISO), approximately 30% of equipment downtime is attributed to bearing issues, underscoring the importance of making informed choices when it comes to these critical components.

With various alternatives available, including angular contact and self-aligning ball bearings, understanding the unique requirements of your application is essential. This blog will explore the different types of Groove Ball Bearings, highlighting key considerations and best practices to ensure that you select the most suitable option for your industrial needs.

When selecting groove ball bearings for industrial applications, it’s essential to understand the different types available and their specific functions. Groove ball bearings are designed with a deep groove that accommodates radial and axial loads, making them versatile for various machinery.

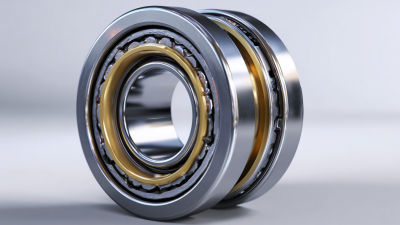

The two primary types are single-row and double-row groove ball bearings. Single-row bearings are more common and suitable for applications where space is limited, whereas double-row bearings offer increased load capacity, making them ideal for high-load scenarios.

The two primary types are single-row and double-row groove ball bearings. Single-row bearings are more common and suitable for applications where space is limited, whereas double-row bearings offer increased load capacity, making them ideal for high-load scenarios.

In addition to the number of rows, groove ball bearings can also differ in material composition, with options such as steel, ceramic, and stainless steel. Steel bearings are robust and suitable for most industrial applications, while ceramic bearings offer lower friction and higher wear resistance but at a higher cost. Stainless steel bearings provide excellent corrosion resistance, making them a preferred choice in environments exposed to moisture. By considering the specific needs of your application, including load conditions and environmental factors, you can effectively choose the right type of groove ball bearing that ensures optimal performance and longevity in your industrial setting.

When selecting groove ball bearings for industrial applications, several key factors come into play to ensure optimal performance and longevity. One primary consideration is the load capacity of the bearings. According to the AFBMA (Anti-Friction Bearing Manufacturers Association), the dynamic load rating is crucial, as it indicates the maximum load a bearing can sustain while maintaining its operational efficiency. Selecting bearings that can handle the specific load requirements of your application is vital, as underestimating load can lead to premature failure.

Another important factor is the operating environment. Bearings exposed to extreme temperatures, humidity, or contaminants require specialized materials and seals to prolong their service life. A report by the International Federation of Robotics highlights that nearly 30% of bearing failures can be attributed to environmental conditions. Thus, evaluating the operating conditions and choosing the right material—such as stainless steel for corrosion resistance or ceramic for high-temperature applications—can significantly impact performance and reliability.

Finally, it’s essential to consider the speed rating of the bearings. The maximum operational speed affects everything from efficiency to wear over time. According to Timken, it is critical to match the bearing's speed specifications with your application’s requirements, as exceeding these ratings can lead to increased heat generation and eventual failure. By carefully assessing these factors, industries can select groove ball bearings that align closely with their operational needs, ensuring smoother operations and reduced downtime.

When selecting groove ball bearings for industrial applications, evaluating load capacity and speed ratings is crucial. Load capacity is the maximum weight that a bearing can safely support. It is typically defined by two primary measures: static load rating (the load the bearing can withstand while stationary) and dynamic load rating (the load it can handle during rotation). Understanding these ratings helps ensure that the selected bearings can sustain the demands of your machinery without risk of premature failure.

Speed ratings play a vital role too, as they indicate the maximum operational speed of a bearing. Exceeding this speed can lead to overheating, wear, and eventual breakdown. It is essential to consider the operational environment, including factors like lubrication and temperature, which can affect performance. Choosing bearings with appropriate load capacities and speed ratings tailored to your specific application can enhance reliability and efficiency, ultimately contributing to smoother operations in industrial settings.

When it comes to ensuring the longevity and optimal performance of groove ball bearings in industrial applications, proper maintenance is paramount. Regular inspections should be conducted to identify any signs of wear or damage. Pay close attention to any unusual noises or vibrations, as they can indicate misalignment or insufficient lubrication. Developing a routine maintenance schedule can help preemptively address these issues before they escalate into significant failures.

Lubrication plays a critical role in extending the lifespan of groove ball bearings. Selecting the right type of lubricant based on the operating conditions—such as temperature, load, and speed—is essential. Both grease and oil have their advantages; grease can provide better sealing, while oil is more effective in dissipating heat. It is also important to ensure that the bearings are not over-lubricated, as excess lubricant can lead to increased heat and potential bearing malfunction. Implementing these best practices not only enhances performance but also minimizes downtime and costs associated with bearing replacements.

This chart illustrates the performance of various groove ball bearings based on load capacity and durability for industrial applications.

When selecting groove ball bearings for industrial applications, it's crucial to steer clear of common pitfalls that can lead to operational inefficiencies or premature failure. One of the most frequent mistakes is overlooking the specifications of the application. Different tasks may require bearings with varying load capacities, speed ratings, and environmental resistance. Failing to match these specifications can result in bearings that either wear out too quickly or do not perform optimally under given conditions.

Another common mistake is neglecting the quality of the bearing. Many may be tempted to choose lower-priced options without considering the long-term costs associated with inferior quality. Low-quality bearings can lead to increased maintenance needs, unexpected downtime, and even the risk of catastrophic failure. It's vital to invest in high-quality bearings that not only meet the performance criteria but also come from reputable manufacturers, ensuring better reliability and longevity in your industrial operations.

| Application | Load Type | Speed Rating (RPM) | Material | Common Mistake |

|---|---|---|---|---|

| Electric Motors | Radial Load | 3000 | Chrome Steel | Ignoring RPM limit |

| Pumps | Axial Load | 2000 | Stainless Steel | Not considering corrosion resistance |

| Conveyor Systems | Combined Load | 1500 | Polymer | Overlooking bearing maintenance |

| Automotive | Radial Load | 4000 | Ceramic | Underestimating temperature tolerance |

| Food Processing | Radial Load | 1200 | FDA approved materials | Neglecting hygiene standards |