In the world of machinery, the choice of bearing can significantly impact the efficiency and durability of equipment. Among various types of bearings, taper roller bearings have gained widespread recognition for their superior performance in heavy-load applications. According to Dr. Emily Johnson, a well-respected expert in bearing technology, "Taper roller bearings are essential for ensuring optimal load distribution and reducing wear, facilitating smoother operation in heavy machinery." This sentiment highlights the pivotal role that taper roller bearings play in enhancing the reliability and lifespan of industrial equipment.

The inherent design of taper roller bearings allows for the accommodation of both radial and axial loads, making them ideal for a range of applications, from automotive to industrial machinery. By enabling precise alignment and minimizing friction, taper roller bearings contribute to heightened operational efficiency and lower maintenance costs. As businesses strive to maximize productivity while minimizing downtime, the choice of components like taper roller bearings becomes increasingly critical. In this article, we will delve deeper into the advantages of incorporating taper roller bearings into your machinery, emphasizing the reasons that make them a preferred choice among industry professionals.

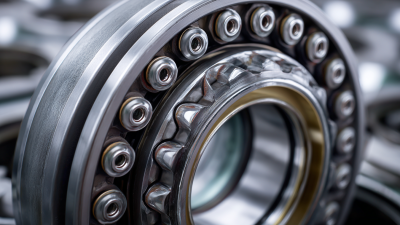

Taper roller bearings are engineered to support both radial and axial loads, making them an ideal choice for a wide range of machinery applications. Their design features an inner and outer ring with tapered surfaces, allowing for optimal alignment and distribution of loads. This geometry not only enhances load-carrying capacity but also helps to reduce friction and heat generation during operation, which is crucial for maintaining the efficiency and longevity of machinery.

One of the key benefits of taper roller bearings is their superior ability to manage varying loads. When subjected to heavy machinery conditions, they effectively distribute the load across a larger contact area. This results in improved stability and reduces the risk of damage or premature wear. Furthermore, taper roller bearings are adaptable, allowing them to accommodate changes in load direction or magnitude, which is common in dynamic industrial environments. By utilizing taper roller bearings, machinery operators can ensure consistent performance and reliability, ultimately leading to increased productivity and reduced downtime.

| Dimension | Value | Benefit |

|---|---|---|

| Load Capacity | High | Allows for heavy machinery operation |

| Bearing Arrangement | Tapered | Improves alignment and rotation efficiency |

| Friction | Low | Enhances overall machinery performance |

| Durability | Long-lasting | Reduces maintenance and replacement costs |

| Load Distribution | Uniform | Minimizes stress on machinery components |

| Temperature Resistance | High | Maintains performance in extreme conditions |

Taper roller bearings are essential components in various industries due to their unique ability to handle both radial and axial loads effectively. This makes them particularly valuable in applications such as automotive manufacturing, where they are used in wheel hubs, transmissions, and differential assemblies. According to a report by MarketsandMarkets, the automotive sector alone is projected to consume over 40% of the total taper roller bearings market by 2026, highlighting the critical role these bearings play in ensuring vehicle performance and longevity.

In the industrial machinery sector, taper roller bearings facilitate smooth operation in heavy equipment and machinery, including conveyor systems, gearboxes, and construction equipment. The global demand for these bearings in industrial applications is expected to reach approximately USD 3 billion by 2025. Their capacity to distribute load over a larger surface area significantly reduces wear and increases the lifespan of machinery components. Furthermore, the ability to withstand high temperatures and harsh environmental conditions makes taper roller bearings a preferred choice in sectors such as mining and metallurgy, further showcasing their versatility and reliability across diverse applications.

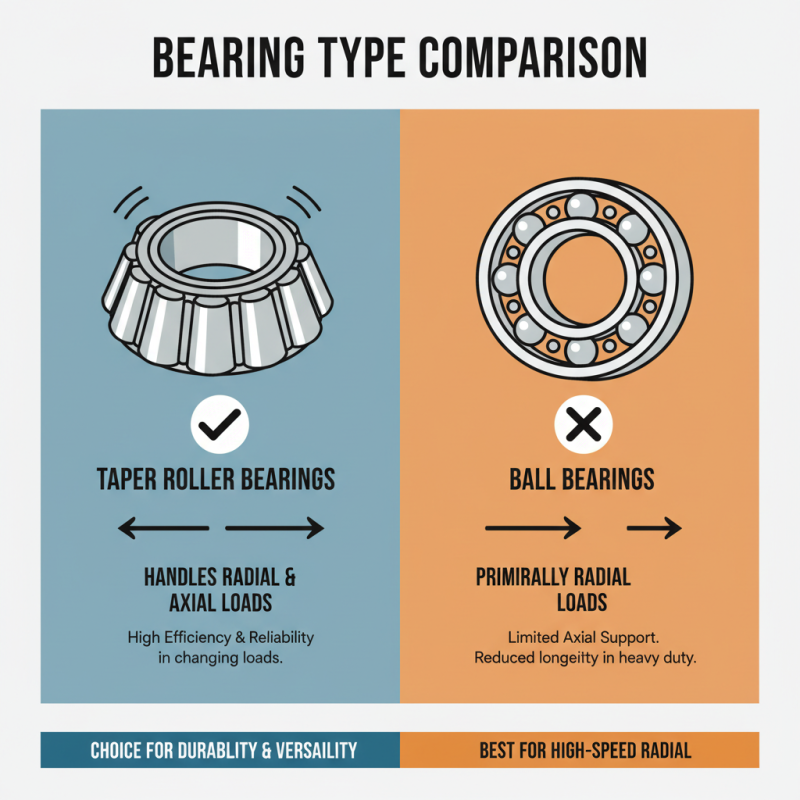

When considering the appropriate bearing type for machinery, taper roller bearings stand out distinctly against other alternatives. One significant advantage of taper roller bearings is their ability to handle both radial and axial loads with high efficiency. This characteristic enables them to maintain performance reliability in applications where load directions frequently change. In contrast, ball bearings primarily excel in supporting radial loads and typically fall short when subjected to axial forces. This limitation can affect their longevity and operation in heavy-duty environments.

Additionally, taper roller bearings are engineered with a unique design that facilitates better contact with the raceways, promoting smoother operation and reduced friction. This feature contrasts with other bearing types like spherical bearings, which can experience higher levels of wear and greater heat generation under similar loads. The increased contact area allows taper roller bearings to distribute loads more evenly, contributing to their robustness and durability, making them an outstanding choice for complex machinery applications where reliability is paramount.

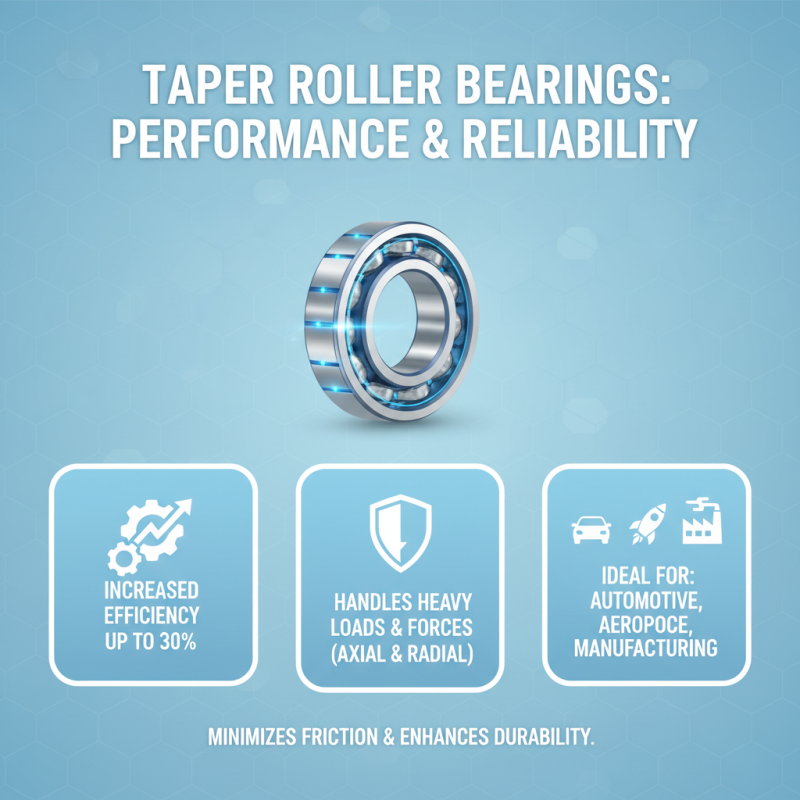

When considering the performance and reliability of taper roller bearings, industry statistics reveal their significant advantages in various machinery applications. These bearings excel in handling heavy loads and taking axial and radial forces, making them a favored choice in sectors such as automotive, aerospace, and manufacturing. Research indicates that taper roller bearings can increase machinery efficiency by up to 30% due to their specialized design that minimizes friction and enhances durability.

Moreover, reliability is a critical factor in operational success, and taper roller bearings have shown exceptional performance in longevity tests. Studies suggest that equipment fitted with high-quality taper roller bearings experiences fewer breakdowns and maintenance needs, translating to reduced operational costs and increased productivity. The statistical evidence supports the idea that incorporating these bearings into machinery design can lead to significant operational benefits, affirming their role as an essential component in achieving optimal machinery performance.

When it comes to heavy machinery, the selection of the right bearing can significantly influence operational efficiency and equipment longevity. Taper roller bearings, known for their ability to handle both radial and axial loads, are often the go-to choice for manufacturers and operators alike. However, proper maintenance is crucial to ensure these bearings perform at their best and to extend their lifespan. According to a report from the American Bearing Manufacturers Association (ABMA), nearly 42% of bearing failures stem from inadequate lubrication and maintenance practices. Therefore, adhering to best practices for taper roller bearing maintenance is essential.

One tip for optimal maintenance is to regularly check and maintain lubrication levels. Taper roller bearings require proper lubrication to reduce friction and wear. Operators should ensure that the lubrication is suitable for the operating temperatures and conditions, as this can dramatically increase bearing life. Furthermore, maintaining a clean environment around the bearings is critical. Dust and contaminants can lead to premature bearing failure, as highlighted in research by the Bearing Research Group, which estimates that contaminants account for about 30% of bearing-related issues in industrial settings.

Another important practice is to conduct frequent inspections of the bearing condition. Look for any signs of wear, misalignment, or unusual noise. Tools like vibration analysis and infrared thermography can provide valuable insights into the health of the bearings. Innovative technology, as reported by the International Journal of Mechanical Engineering, has shown that predictive maintenance can reduce unplanned downtime by up to 70%. Regular monitoring and preventative measures can ensure smoother operations, ultimately saving costs on repairs and replacements.