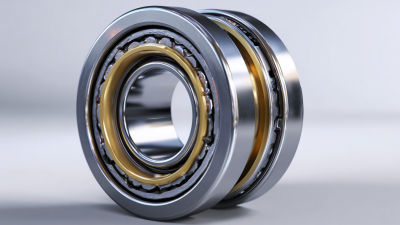

Choosing the right cylindrical roller bearing (CRB) is crucial for optimizing machinery performance and ensuring longevity in various industrial applications. According to a recent report by the Global Bearings Market, the cylindrical roller bearing segment is projected to grow at a CAGR of 5.2% through 2027, driven by increasing demand from sectors such as automotive, aerospace, and manufacturing. The design characteristics of CRBs, including their ability to handle high radial loads and their unique configurations, make them suitable for applications ranging from electric motors to heavy machinery. However, with a wide array of types and specifications available, selecting the appropriate CRB can be challenging. Understanding load ratings, operating conditions, and material considerations is essential for engineers to make informed decisions. This guide aims to simplify the selection process for cylindrical roller bearings by highlighting key factors that influence performance and reliability in diverse industrial scenarios.

When selecting cylindrical roller bearings for specific applications, understanding load capacity requirements is essential for optimizing performance. The load capacity of a bearing is defined by its ability to support radial and axial loads. Factors such as the type of load, the operational environment, and the expected lifespan of the bearing must be carefully evaluated. For instance, applications involving heavy machinery may necessitate bearings with higher load ratings to prevent premature failure.

Additionally, it's crucial to consider the dynamic and static load ratings provided by manufacturers. These ratings indicate the maximum loads that can be applied without causing deformation or fatigue. It's also vital to assess the alignment and mounting conditions, as they can affect the bearing's load distribution. By ensuring that the selected cylindrical roller bearing meets or exceeds load capacity requirements, you can enhance durability and reliability in your application, ultimately leading to improved operational efficiency.

When selecting a cylindrical roller bearing for your specific applications, it is crucial to evaluate the operating conditions, particularly temperature, speed, and lubrication. Operating at high temperatures can lead to oxidative degradation of lubricants, significantly impacting bearing performance and service life. Recent studies indicate that reducing lubricant viscosity can improve fuel economy in passenger vehicles, yet it poses risks for wear protection if not adequately managed. Therefore, understanding the viscosity requirements in relation to the bearing's operational environment is fundamental for ensuring reliability and efficiency.

Moreover, effective lubrication strategies must consider not only the choice of lubricant but also its oxidation stability under varying temperature conditions. Non-isothermal thermogravimetric analysis has shown that certain lubricants exhibit significantly different induction times and oxidative properties, influencing their suitability for high-temperature applications. Utilizing advanced condition monitoring and predictive modelling, such as the Circumferential Grooved Bearing (CGB) model, can also provide insights into the hydrodynamic lubrication behavior under diverse operational conditions, thus aiding in making informed decisions when selecting cylindrical roller bearings.

When selecting a cylindrical roller bearing for your application, understanding the material types and their impact on bearing life and durability is crucial. Different materials offer varying levels of resistance to wear, corrosion, and temperature fluctuations. For instance, high-carbon chromium steel is commonly used for its excellent performance under high loads and temperatures. However, other materials like stainless steel or ceramic may be more suitable for environments exposed to moisture or chemicals.

**Tip:** Always consider the operating environment when choosing bearing materials. Stainless steel bearings are ideal for applications where corrosion is a concern, while ceramic materials can significantly enhance performance in extreme temperatures.

Additionally, the heat treatment of the bearing material can affect hardness and wear resistance. Bearings that undergo processes like tempering or quenching may have enhanced durability, making them resistant to fatigue failure. This consideration is significant for applications subject to dynamic loads or constant operational stress.

**Tip:** Opt for suppliers who provide detailed specifications and testing results on their materials, ensuring that the bearings meet your specific application needs. Proper material selection can lead to longer bearing life and reduced maintenance costs.

When selecting the appropriate cylindrical roller bearing for specific applications, it is essential to analyze bearing dimensions and clearances thoroughly to enhance functionality. A recent report by the International Journal of Engineering Research and Applications indicates that improper clearance can lead to significant operational issues, including increased wear and premature failure. The optimal clearance can vary based on factors like load conditions and temperature ranges, underscoring the importance of precise measurement during the selection process.

According to data from the Roller Bearing Manufacturers Association, cylindrical roller bearings are particularly sensitive to fit and radial clearance. For example, an ideal radial clearance ranges between 0.01 mm to 0.05 mm, depending on the application. Engineers should consider the outer and inner diameter, as well as the width, to ensure optimal performance. Adjusting these dimensions not only affects load-carrying capacity but also influences the overall operational efficiency, potentially reducing energy consumption by up to 15%. Thus, a meticulous approach to dimensions and clearances is fundamental for achieving enhanced performance and reliability in various industrial applications.

This chart illustrates the relationship between the load capacity and clearance levels of various cylindrical roller bearings, helping to guide selection for specific applications.

When selecting cylindrical roller bearings for specific applications, adherence to industry standards and specifications is crucial to ensure both compliance and reliability. Different industries may utilize various standards, such as ISO, ANSI, or ASTM, which provide guidelines on dimensions, tolerances, and material properties. Understanding these standards can help in choosing bearings that meet operational requirements, ensuring their performance is predictable and dependable.

Additionally, it is imperative to consider factors like load capacity, speed ratings, and operating environments when reviewing the relevant specifications. For instance, high-load applications may necessitate bearings designed with enhanced durability and stress resistance. It’s also important to validate that the bearings chosen conform to pertinent regulations, which can vary by industry. Regularly consulting updated standards helps in making informed decisions, ultimately leading to improved equipment longevity and operational efficiency.