In the global manufacturing landscape, standard ball bearings play a crucial role in ensuring the efficiency and reliability of machinery across various industries. According to a recent report by MarketsandMarkets, the ball bearing market is projected to reach USD 100.5 billion by 2025, growing at a CAGR of 5.2% from 2020 to 2025. This remarkable growth underscores the increasing demand for high-quality standard ball bearings, particularly as manufacturers seek to enhance operational performance and reduce downtimes. With China's reputation as a manufacturing powerhouse, it is essential for sourcing professionals to understand the nuances of procuring standard ball bearings that meet global standards of excellence. This blog aims to provide a comprehensive checklist that aids in identifying the best sources for standard ball bearings, ensuring that manufacturers not only leverage China's competitive advantages but also fulfill their quality and service-oriented objectives on a global scale.

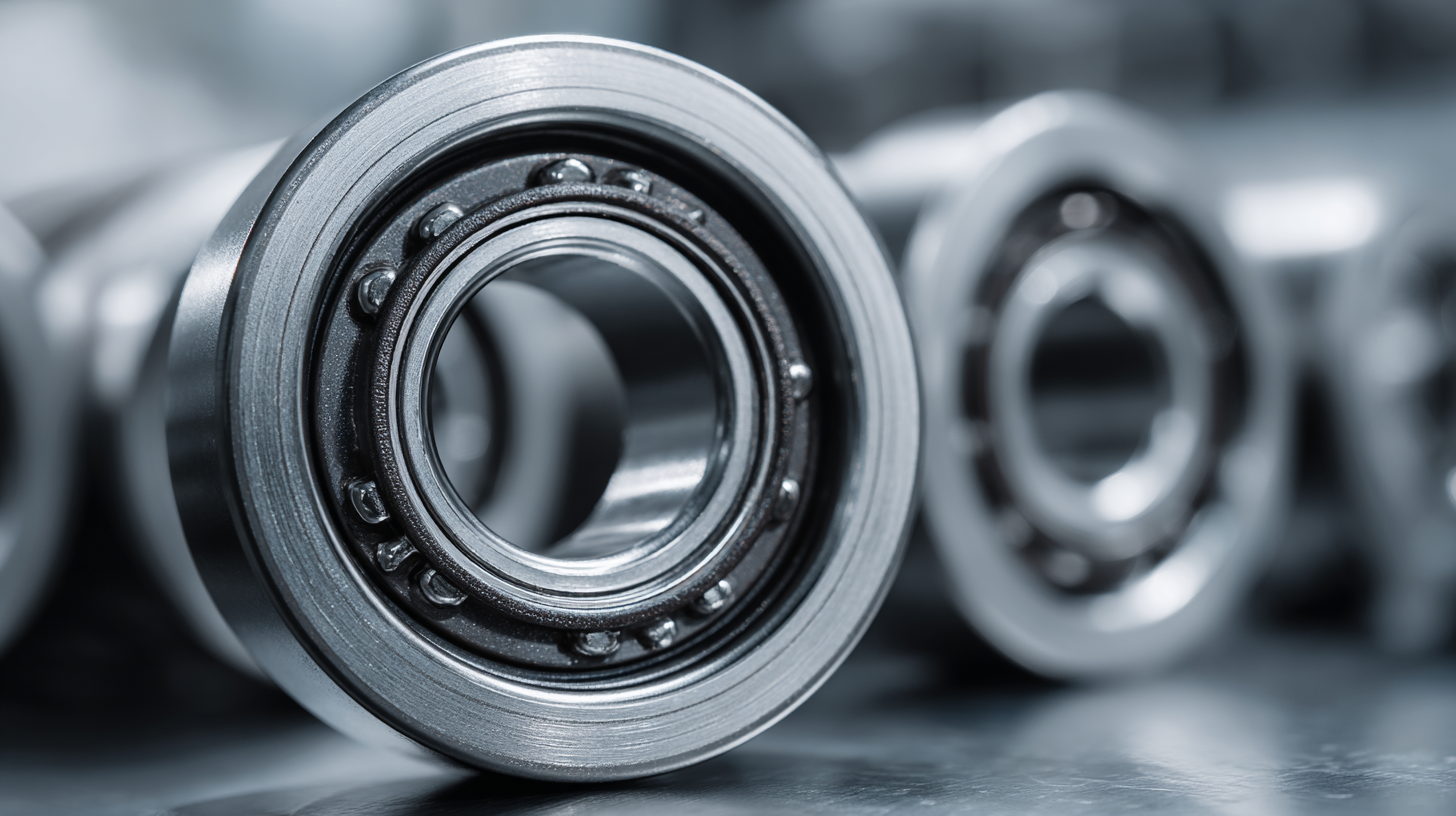

When selecting standard ball bearings, there are several key features to consider that can significantly impact performance and longevity. The first important factor is the material from which the bearing is made. Typically, materials such as stainless steel, chrome steel, and plastic are common choices. Stainless steel offers excellent corrosion resistance, making it ideal for humid or wet environments, while chrome steel is known for its strength and durability. For specialized applications, plastic ball bearings can provide essential benefits like lower weight and resistance to various chemicals.

Another critical feature to pay attention to is the bearing's size and load rating. The size will affect the bearing's ability to fit into your equipment, while the load rating determines how much weight it can support without failing. Properly matching these specifications to your application is crucial for operational efficiency. Additionally, the lubrication type—whether it’s grease or oil—plays a significant role in reducing friction and wear. Lastly, consider the bearing's sealing options, as sealed or shielded bearings can offer protection from contaminants, enhancing their lifespan and reliability in demanding environments.

When sourcing ball bearings, asking the right questions can significantly impact the quality of your procurement process. Start by inquiring about the supplier's manufacturing capabilities. Understanding their production capacity and the technology used will help you gauge whether they can meet your specific requirements. It's also essential to ask about their quality control measures. Requesting information on certifications and testing procedures ensures that the ball bearings you receive meet industry standards.

Another crucial aspect to address is the supplier's delivery timelines and flexibility. Ask how they handle fluctuations in demand and what their lead times are for different order sizes. Additionally, clarifying the terms for after-sales support can save you from potential disruptions in the future. A reliable supplier should provide ongoing assistance and be willing to address any issues that may arise post-purchase. These essential questions will not only help establish a solid relationship with your suppliers but also ensure that you source the best standard ball bearings globally.

The global ball bearings market is experiencing significant growth, driven by increasing demand across various industries, particularly in automotive and industrial applications. As projected, the market size is expected to rise from $7.26 billion in 2025 to $12.15 billion by 2032, with a compound annual growth rate (CAGR) of 7.6%. This trend highlights the critical role that high-quality ball bearings play in enhancing operational efficiency and reliability in machinery and vehicles.

A comparative analysis of the leading global manufacturers reveals a competitive landscape marked by innovation and strategic partnerships. Companies are focusing on technological advancements to improve the performance and lifespan of their products, including the development of specialized bearings for high-stress applications such as wind turbines. The evolution of these rolling element bearings, particularly for wind turbine main shafts, showcases a blend of academic research and industrial applications aimed at addressing sustainability and efficiency challenges in energy production. As manufacturers strive to capture larger market shares, understanding their strengths and market positioning becomes essential for sourcing the best standard ball bearings.

When sourcing ball bearings, evaluating their quality and performance is paramount to ensure longevity and reliability in applications. According to a recent report by MarketsandMarkets, the global ball bearing market is projected to reach $15.9 billion by 2025, with a growing demand for high-performance bearings in automotive and industrial sectors. This underscores the need for rigorous assessment criteria in the selection process.

One critical factor to consider is the material used in production. Premium-quality ball bearings typically utilize high-grade steel or ceramic materials, enhancing wear resistance and load-bearing capacity. Research from the International Journal of Advanced Manufacturing Technology indicates that ceramic ball bearings can reduce friction by up to 60% compared to traditional steel options, making them ideal for high-speed applications. Additionally, manufacturers should prioritize bearings with superior seals and lubrication systems to prevent contamination, which can significantly impact performance and lifespan. Evaluating these characteristics helps buyers make informed decisions that will lead to improved operational efficiency and reduced maintenance costs.

When considering cost-effective strategies for procuring standard ball bearings, it is essential to evaluate alternatives that not only fit the budget but also enhance durability. Recent studies indicate that thermoplastic bushings can outperform standard roller bearings in terms of longevity and maintenance costs. For instance, typical roller bearings may require replacement every 10,000 operational hours, whereas thermoplastic alternatives can extend that to 20,000 hours, offering a significant reduction in replacement frequency.

**Tip:** Prioritize evaluating supplier reliability and material quality when sourcing bearings. A thorough analysis of supplier performance metrics can lead to better procurement decisions.

Moreover, leveraging bulk purchasing agreements can significantly decrease per-unit costs. Industry reports suggest that organizations that negotiate long-term contracts for bearings can achieve discounts of up to 20% compared to spot market prices. This not only lowers the overall procurement budget but also secures a stable supply chain, essential for uninterrupted production.

**Tip:** Consider integrating predictive maintenance technology to maximize bearing lifespan and reduce operational downtime. Advanced analytics can help identify wear patterns and prevent premature failures, ultimately leading to cost savings.

| Parameters | Criteria | Details | Cost-Effectiveness Strategies |

|---|---|---|---|

| Material | Stainless Steel | Corrosion resistant, suitable for harsh conditions | Negotiate bulk purchase discounts |

| Size | Varies (e.g., 6201, 6202) | Standard sizes commonly used in various applications | Consider local suppliers for reduced shipping costs |

| Application | Automotive, Industrial Machines | Essential for reducing friction in rotating components | Research similar applications for competitive pricing |

| Supplier Reliability | ISO Certified | Ensure consistent quality and adherence to standards | Request samples before placing large orders |

| Lead Time | 2-4 weeks | Time needed for production and delivery | Plan orders ahead to accommodate production schedules |