In the ever-evolving landscape of industrial applications, the demand for precision-engineered components is on the rise. Among these, the Double Taper Roller Bearing stands out as a pivotal element that enhances performance and reliability. According to a report by the Markets and Markets Research, the global bearing market is projected to grow from USD 85.5 billion in 2020 to USD 102.8 billion by 2025, highlighting the critical role of high-quality bearings in various industries, including automotive, aerospace, and manufacturing. As industries strive for improved efficiency and longevity of machinery, the selection of the right suppliers becomes paramount. This blog will delve into the benefits of using Double Taper Roller Bearings, while also providing top strategies for identifying quality suppliers that can meet the rigorous demands of modern industrial applications.

In the ever-evolving landscape of industrial applications, the demand for precision-engineered components is on the rise. Among these, the Double Taper Roller Bearing stands out as a pivotal element that enhances performance and reliability. According to a report by the Markets and Markets Research, the global bearing market is projected to grow from USD 85.5 billion in 2020 to USD 102.8 billion by 2025, highlighting the critical role of high-quality bearings in various industries, including automotive, aerospace, and manufacturing. As industries strive for improved efficiency and longevity of machinery, the selection of the right suppliers becomes paramount. This blog will delve into the benefits of using Double Taper Roller Bearings, while also providing top strategies for identifying quality suppliers that can meet the rigorous demands of modern industrial applications.

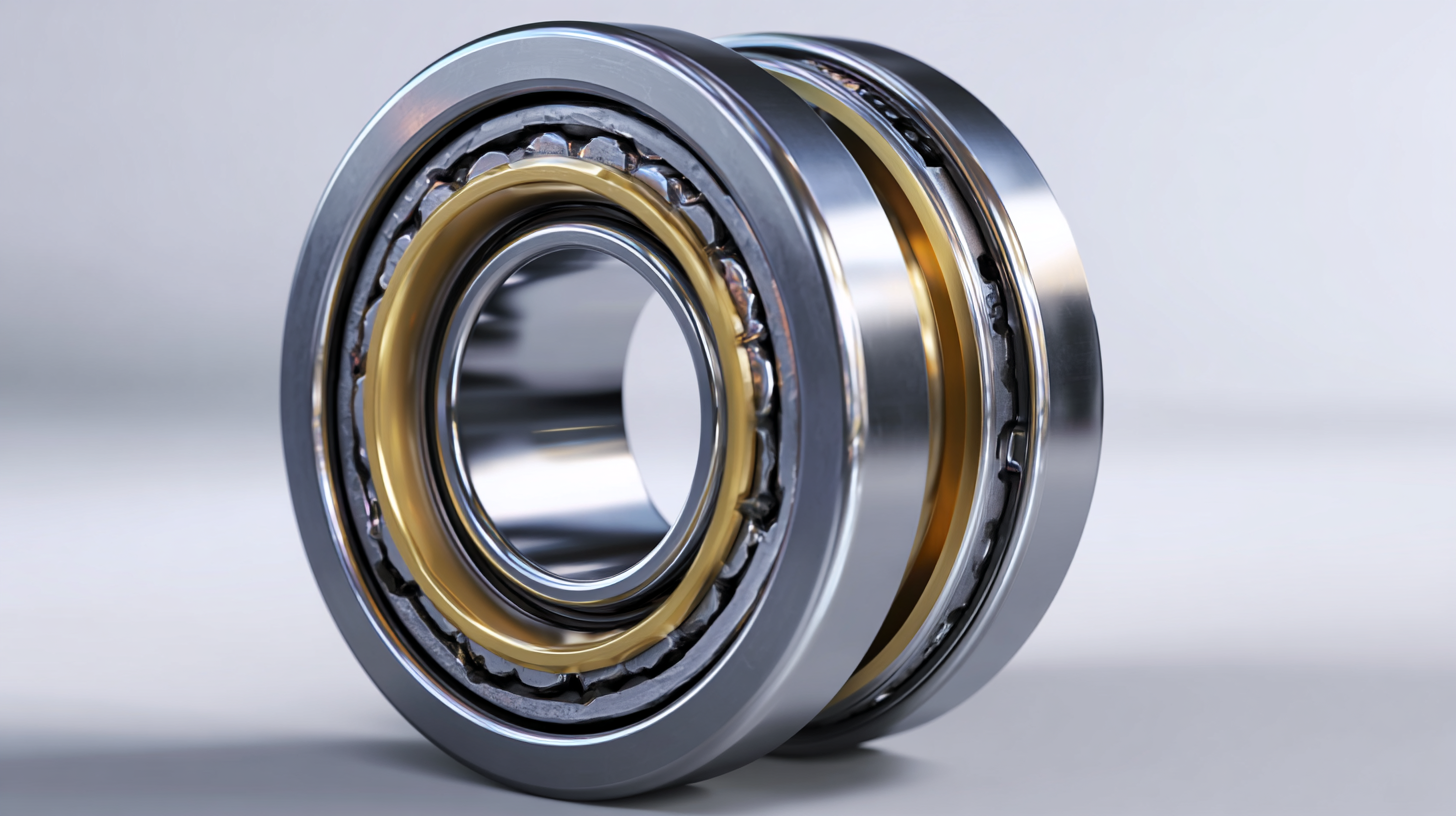

Double taper roller bearings are engineered to handle significant axial and radial loads, making them an essential component in various industrial applications. With their unique design, these bearings facilitate effective load distribution, which not only enhances the longevity of mechanical systems but also minimizes the risk of failure. In the railroad industry, for example, these bearings endure extreme conditions, necessitating regular health inspections to ensure optimal performance. Their ability to operate smoothly under high load and speed conditions makes them ideal for freight railcar bearings, which are crucial for the safe transportation of goods.

Double taper roller bearings are engineered to handle significant axial and radial loads, making them an essential component in various industrial applications. With their unique design, these bearings facilitate effective load distribution, which not only enhances the longevity of mechanical systems but also minimizes the risk of failure. In the railroad industry, for example, these bearings endure extreme conditions, necessitating regular health inspections to ensure optimal performance. Their ability to operate smoothly under high load and speed conditions makes them ideal for freight railcar bearings, which are crucial for the safe transportation of goods.

The technical specifications of double taper roller bearings are critical for industries that prioritize efficiency and reliability. These bearings typically feature a tapered roller configuration that allows them to accommodate combined loads, thus improving overall operational stability. Key specifications include the bearing's dynamic and static load ratings, noise levels, and material composition, all of which contribute to their performance in demanding applications. By adhering to these specifications, industries can ensure that they select the right bearings that meet their specific operational needs, ultimately leading to enhanced machinery performance and reduced maintenance costs.

Double taper roller bearings have emerged as a preferred choice in various industrial applications, thanks to their unique design and impressive capabilities. One of the key advantages of these bearings is their ability to handle both radial and axial loads. This dual-functionality makes them ideal for applications where space is limited, allowing for a more compact design without sacrificing performance.

Industries like automotive, manufacturing, and heavy machinery particularly benefit from this feature, as it leads to enhanced efficiency and reduced maintenance needs.

Double taper roller bearings have emerged as a preferred choice in various industrial applications, thanks to their unique design and impressive capabilities. One of the key advantages of these bearings is their ability to handle both radial and axial loads. This dual-functionality makes them ideal for applications where space is limited, allowing for a more compact design without sacrificing performance.

Industries like automotive, manufacturing, and heavy machinery particularly benefit from this feature, as it leads to enhanced efficiency and reduced maintenance needs.

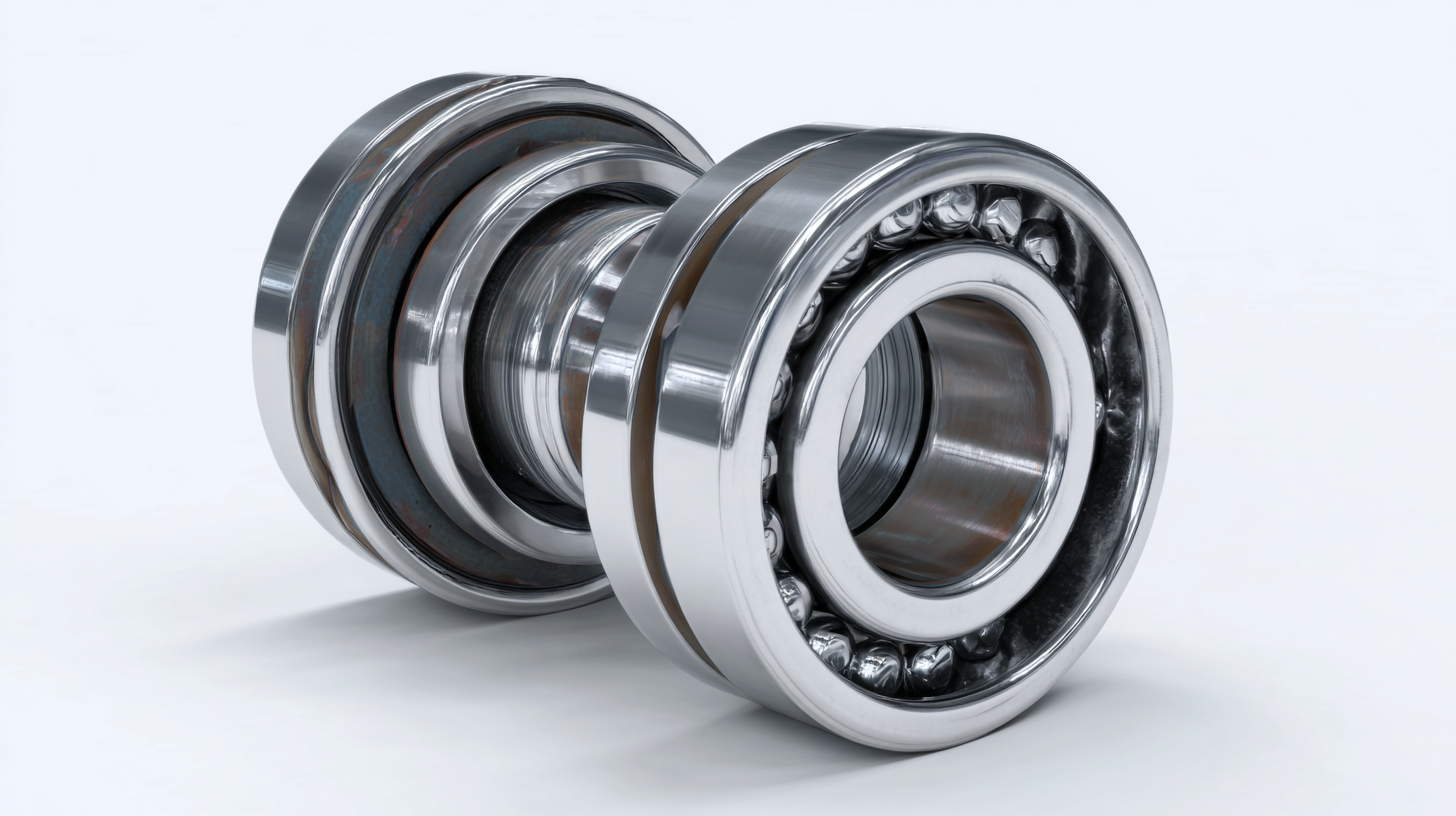

Another significant benefit of double taper roller bearings is their high rigidity and stability under load. This characteristic ensures smoother operation, minimizes vibrations, and extends the lifespan of machinery components. In challenging environments where equipment is subjected to heavy use and extreme conditions, these bearings offer the durability needed to maintain operational reliability. Furthermore, the ease of installation and replacement further contributes to lower downtime, making double taper roller bearings an economical choice for industries aiming to optimize their processes.

When selecting the right double taper roller bearing for your business needs, it’s crucial to consider various factors that directly impact performance and efficiency. The design of double taper roller bearings allows for handling both radial and axial loads, making them suitable for diverse industrial applications, such as in the manufacturing of food blenders and mixers. This specificity is particularly important in today's fast-paced market, where the demand for convenient and ready-to-eat products is surging.

To ensure optimal performance, evaluate the load capacity, dimensional attributes, and material composition of the bearings. Each application, whether in heavy machinery or food processing equipment, will have unique requirements based on the operational environment and expected load conditions. Additionally, consider the bearing's ability to withstand contamination and high temperatures, which are often prevalent in the food industry. By meticulously analyzing these factors, businesses can make informed decisions that enhance productivity and extend the lifespan of their machinery.

When it comes to double taper roller bearings, proper maintenance is essential to maximize their lifespan and ensure optimal performance. Regular inspections can help identify potential issues before they escalate. It’s advisable to check for signs of wear, such as unusual noises or vibrations, which can indicate that the bearings may need servicing or replacement.

Another critical aspect of maintenance is lubrication. Ensuring that the bearings are adequately lubricated helps to reduce friction and prevent overheating. It is recommended to follow the manufacturer’s guidelines regarding lubrication intervals and choose the right type of grease or oil specifically designed for double taper roller bearings. Clean the bearings thoroughly during each service to remove any contaminants that could hinder their functionality.

Lastly, proper installation and alignment can significantly impact the longevity of double taper roller bearings. Take the time to ensure that the bearings are installed correctly, avoiding excessive axial or radial loads. This attention to detail during setup can help prevent premature failure and enhance the overall efficiency of the machinery in which they are used.

Double taper roller bearings have gained significant attention in various industrial applications due to their unique design and enhanced performance characteristics. In sectors such as automotive manufacturing, aerospace, and heavy machinery, these bearings provide superior load distribution and stability. According to a report by Grand View Research, the global bearing market is projected to reach $100 billion by 2025, emphasizing the growing reliance on advanced bearing technologies like double taper roller bearings.

In the automotive industry, double taper roller bearings are increasingly utilized in wheel hubs and differential systems. Their ability to handle both radial and axial loads makes them ideal for high-speed applications. A study conducted by Research and Markets indicates that the automotive segment alone is expected to witness a CAGR of 4.5% from 2023 to 2030, driven by the demand for more efficient and durable components. Similarly, in aerospace applications, the lightweight yet robust nature of these bearings helps to reduce overall aircraft weight, contributing to improved fuel efficiency and performance.

Furthermore, in heavy machinery and construction equipment, double taper roller bearings play a crucial role in enhancing operational reliability. The increased life span and reduced maintenance requirements align with industry goals for greater uptime and efficiency. With an annual growth rate of 5.6% in the machine tools market, according to Allied Market Research, the adoption of high-performance bearings like the double taper roller type is vital for meeting the demands of modern industrial machinery.