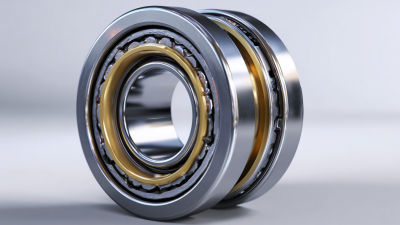

The U Groove Roller Bearing has emerged as a pivotal component in modern machinery, offering exceptional performance and durability across various applications. Characterized by its unique groove design, this bearing type enhances load distribution and minimizes friction, ultimately leading to increased efficiency and longevity in mechanical systems.

As industries strive for innovation and reliability, the U Groove Roller Bearing provides a solution that not only meets but exceeds the demands of contemporary engineering challenges. From conveyor systems to automated machinery, its versatility makes it indispensable in enhancing operational effectiveness.

This article delves into the myriad benefits and applications of U Groove Roller Bearings, illustrating why they have become a preferred choice for engineers and manufacturers alike. As we explore these advantages, we will also highlight the transformative impact these bearings have on machinery performance and maintenance strategies in today's fast-paced industrial landscape.

As industries strive for innovation and reliability, the U Groove Roller Bearing provides a solution that not only meets but exceeds the demands of contemporary engineering challenges. From conveyor systems to automated machinery, its versatility makes it indispensable in enhancing operational effectiveness.

This article delves into the myriad benefits and applications of U Groove Roller Bearings, illustrating why they have become a preferred choice for engineers and manufacturers alike. As we explore these advantages, we will also highlight the transformative impact these bearings have on machinery performance and maintenance strategies in today's fast-paced industrial landscape.

U groove roller bearings are increasingly recognized for their advantages in high-load applications, where traditional bearings may struggle. These unique roller bearings are designed with a U-shaped groove that allows for a deeper roller path, facilitating better load distribution. This design ensures that even under heavy stress, the load is spread evenly across the rollers, minimizing the wear and tear typically associated with high-load scenarios. As a result, U groove roller bearings not only enhance the lifespan of machinery components but also reduce the frequency of maintenance interventions, leading to cost savings over time.

U groove roller bearings are increasingly recognized for their advantages in high-load applications, where traditional bearings may struggle. These unique roller bearings are designed with a U-shaped groove that allows for a deeper roller path, facilitating better load distribution. This design ensures that even under heavy stress, the load is spread evenly across the rollers, minimizing the wear and tear typically associated with high-load scenarios. As a result, U groove roller bearings not only enhance the lifespan of machinery components but also reduce the frequency of maintenance interventions, leading to cost savings over time.

In addition to their durability, U groove roller bearings provide increased rigidity and stability in demanding environments. Their construction allows for greater resistance to deformation when subjected to high loads, which is crucial in industries such as heavy machinery, automotive, and materials handling. The enhanced performance characteristics of these bearings lead to smoother operational efficiencies, ultimately improving the overall productivity of the machinery. This makes U groove roller bearings a preferred choice for engineers and manufacturers looking to optimize performance and reliability in high-load applications.

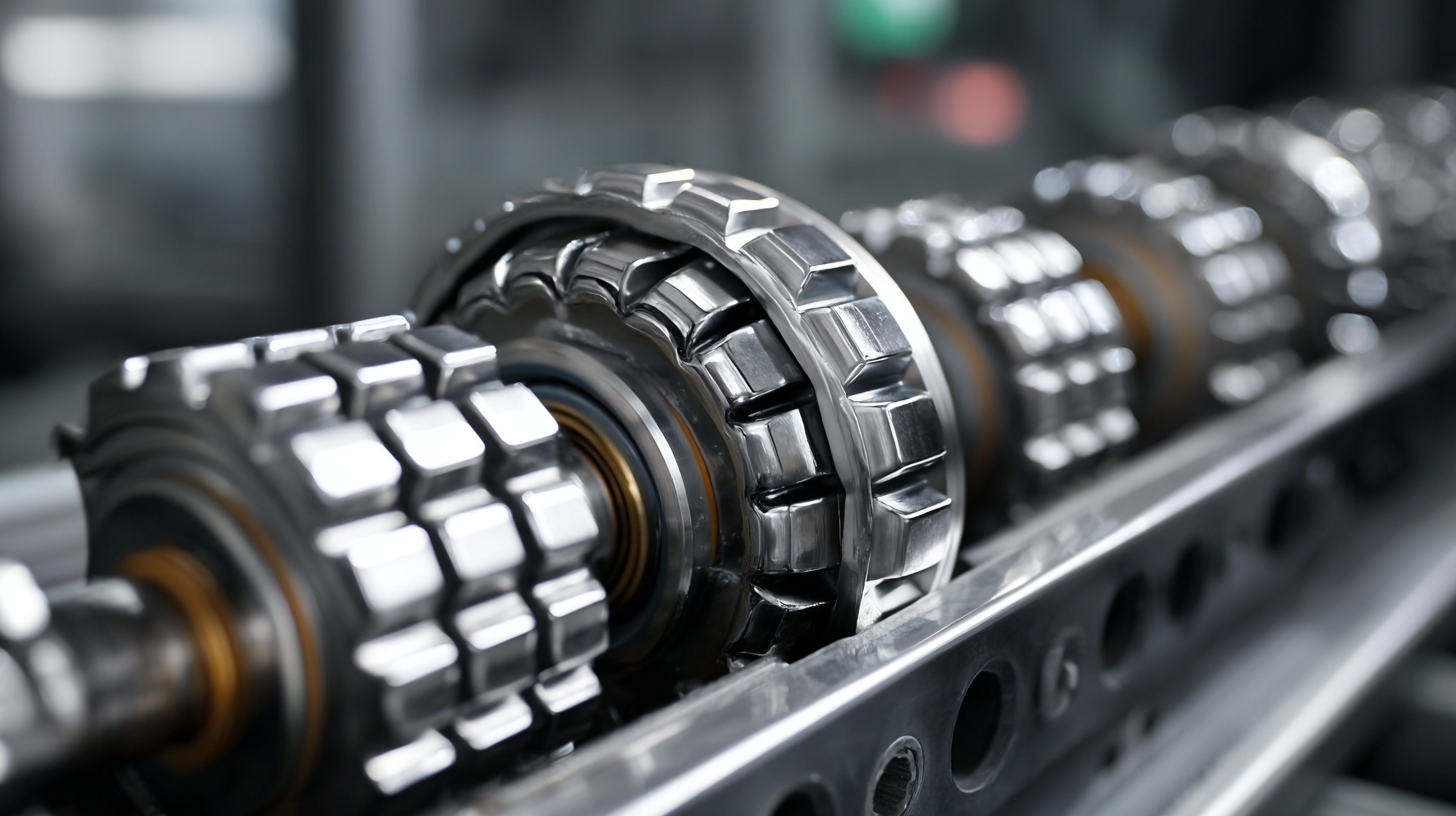

U Groove roller bearings have gained significant traction in modern automated machinery due to their unique design and versatility. These bearings provide excellent rotational accuracy and load distribution, making them ideal for applications in automated systems where precision is paramount. Their U-shaped groove allows for smooth travel along guide rails, reducing friction and wear which enhances the overall lifespan of equipment. As industries increasingly lean towards automation, the demand for efficient and reliable bearing solutions like U Groove roller bearings is on the rise.

The expanded use of U Groove roller bearings can be observed in various automated applications, including conveyor systems, robotic arms, and high-speed machinery. The design of these bearings facilitates seamless integration into complex mechanisms that require consistent performance under varying loads and speeds. Moreover, as the global bearings market is projected to grow substantially, the adaptability of U Groove roller bearings positions them as a crucial component in advancing automation technology, contributing to improved efficiency and reduced operational costs in modern industries.

U Groove roller bearings

play a critical role in enhancing the performance

of modern machinery. As components designed to support rotating shafts, these bearings minimize friction and wear during operation. With the global bearings market projected to grow from

USD 50.16 billion in 2025 to

USD 97.10 billion by 2032, the significance of selecting the right bearing type becomes increasingly clear. U Groove roller bearings, specifically, offer

superior load-carrying capabilities

and stability, making them ideal for applications that demand high precision and durability.

Additionally, the impact of U Groove roller bearings on equipment longevity cannot be overstated. By reducing wear and tear, they contribute to a significant decrease in maintenance costs and downtime. Industry reports highlight that efficient bearing solutions can lead to enhanced overall equipment effectiveness, particularly in sectors such as automotive and manufacturing. As manufacturers continue to seek innovations in bearing technology, the adoption of U Groove roller bearings is likely to increase, driving advancements in machinery performance and reliability. Their importance in optimizing operational efficiency and extending equipment lifespan will remain a focal point as the bearings market evolves.

U Groove roller bearings have emerged as an innovative solution in machinery design, offering distinct advantages over traditional bearing types such as ball bearings and plain bearings. Unlike ball bearings, which rely on point contact and can suffer from higher friction and wear, U Groove roller bearings provide a larger contact area thanks to their cylindrical rollers. This design significantly reduces the stress on individual components, leading to enhanced load capacity and improved durability. Additionally, the U-shaped groove accommodates misalignment better, which can be a common challenge in machinery operations.

When compared to plain bearings, U Groove roller bearings exhibit superior performance in dynamic applications. While plain bearings may require more frequent lubrication and maintenance, the roller design of U Groove bearings often extends maintenance intervals due to their lower friction characteristics. Furthermore, they facilitate smoother operation under varying loads and speeds, making them ideal for applications in conveyor systems, robotics, and other high-performance machinery. Overall, the advantages of U Groove roller bearings in terms of load handling, maintenance efficiency, and operational reliability position them as a preferred choice over traditional bearing types in modern engineering applications.

| Feature | U Groove Roller Bearings | Traditional Bearings |

|---|---|---|

| Load Capacity | Higher due to larger contact area | Generally lower, varies by type |

| Friction | Lower friction, enhancing efficiency | Higher friction, potential energy loss |

| Maintenance | Generally requires less maintenance | May require more frequent upkeep |

| Cost | Moderate initial investment | Lower initial cost |

| Application Suitability | Ideal for precision and high-load applications | Used in general applications |

| Durability | Longer lifespan under stress | Shorter lifespan, wear and tear |

The advancements in U groove roller bearing technology are reshaping the landscape of modern machinery. Innovations such as advanced materials, precision manufacturing processes, and enhanced lubrication techniques have significantly improved the performance and longevity of these bearings. For instance, the adoption of lightweight yet resilient materials like composite polymers and advanced ceramics not only boosts durability but also enhances load capacity, making them ideal for high-speed applications.

Moreover, the integration of smart technologies is paving the way for future developments in U groove roller bearings. IoT-enabled sensors can now monitor operating conditions in real time, providing valuable data that allows for predictive maintenance and reduced downtime. This technological synergy ensures optimal performance and enhances the efficiency of various machinery systems. As industries continue to evolve, the role of U groove roller bearings will undoubtedly expand, leading to innovative designs and applications that cater to the demands of modern engineering challenges.