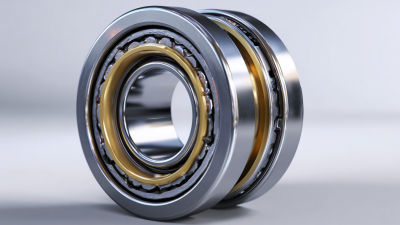

In the realm of heavy industry, where efficiency and reliability are paramount, the choice of bearing type can significantly impact operational performance. Among various bearing solutions, the Double Taper Roller Bearing stands out for its unique design and functional advantages. Engineered to withstand high loads while minimizing friction, this bearing type enhances machinery longevity and reliability. Its tapered profile allows for effective distribution of forces, making it ideal for applications ranging from mining and construction to heavy transportation equipment. Understanding the advantages of Double Taper Roller Bearings not only emphasizes their crucial role in improving mechanical efficiency but also highlights their contribution to reducing maintenance costs and downtime in demanding industrial environments. This exploration will delve into the factors that make Double Taper Roller Bearings indispensable in heavy industry applications, shedding light on their operational benefits and overall significance in advancing industrial capabilities.

Double taper roller bearings are becoming increasingly important in heavy industry applications due to their unique design and operational advantages.

These bearings allow for efficient load distribution, making them ideal for high-pressure environments typical in sectors like manufacturing and heavy machinery. The self-aligning feature helps reduce friction and wear, ensuring longer operational life and reduced maintenance needs.

One of the key features of double taper roller bearings is their ability to handle both radial and axial loads effectively. This characteristic makes them versatile for various industrial applications, from wind turbines to large-scale machinery. Their robust construction also improves performance under extreme conditions, which is critical for industries that operate with heavy loads and in challenging environments.

Tips: When selecting double taper roller bearings for specific applications, consider the load capacities and operational speeds. It's also vital to assess the environmental factors, such as temperature variations and potential contaminants, which can affect bearing performance. Regular maintenance checks can further enhance bearing longevity and operational efficiency, ensuring that machines run smoothly and effectively.

Double taper roller bearings have become increasingly important in heavy industry applications due to their distinct advantages over conventional bearings. These bearings are designed to accommodate both radial and axial loads, providing enhanced stability and performance in high-stress environments. The geometry of double taper roller bearings allows for improved load distribution, which reduces the risk of wear and prolongs the lifespan of machinery. This makes them particularly well-suited for industries such as mining, construction, and transportation, where reliability is crucial.

One of the significant benefits of double taper roller bearings is their ability to handle misalignment, which is often a challenge in heavy machinery. Conventional bearings may suffer from premature failure in such conditions, but the tapered design of double taper bearings ensures that even under misaligned conditions, optimal performance is maintained. Furthermore, as industries increasingly focus on "smart and clean" technologies, these bearings also contribute to energy efficiency, helping to reduce operational costs while meeting modern sustainability standards. Therefore, their adoption is not just a trend but a strategic move towards more resilient and efficient industrial practices.

Double taper roller bearings are crucial components in heavy machinery applications due to their ability to handle high radial and axial loads. This characteristic makes them particularly valuable in heavy industry settings, such as in construction equipment, mining machinery, and industrial compressors. The global bearings market, valued at USD 46.82 billion in 2024, is expected to reach USD 97.10 billion by 2030, highlighting the growing significance of these components in various sectors.

One of the key advantages of double taper roller bearings is their design, which allows for improved load distribution and increased stability during operation. This is particularly beneficial in applications where heavy loads and unexpected stresses are common. Additionally, advancements in fault detection techniques, such as using tunable Q-factor wavelet transform, are enhancing the reliability and longevity of these bearings. Regular condition monitoring can further mitigate the risk of breakdowns, ensuring that machinery operates smoothly.

Tips: When selecting bearings for heavy machinery, consider not only the load capacity but also the environmental conditions they will operate in. Regular maintenance and timely fault detection can significantly extend the life of your machinery. Lastly, investing in quality bearings can lead to fewer breakdowns and reduced operational costs in the long run.

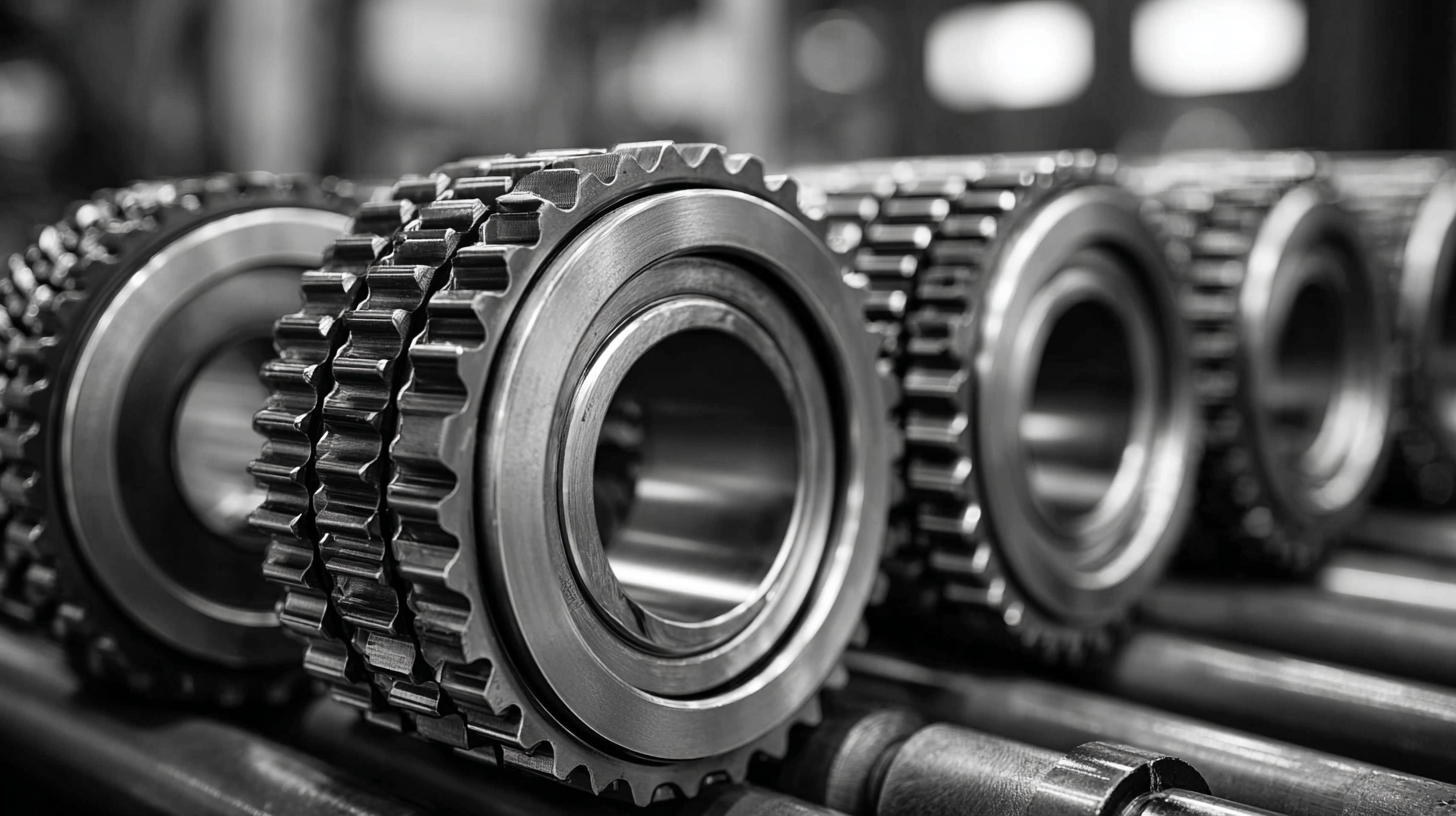

| Application Area | Advantages | Common Use Cases | Load Capacity (kN) | Operating Speed (rpm) |

|---|---|---|---|---|

| Mining Equipment | High radial and axial load capacity | Excavators, crushers | 200 - 600 | 100 - 500 |

| Construction Machinery | Improved stability and endurance | Bulldozers, cranes | 250 - 550 | 80 - 400 |

| Forestry Equipment | Enhanced load distribution | Timber harvesters, forwarders | 180 - 500 | 60 - 350 |

| Agricultural Machinery | Resistance to shock loads | Tractors, harvesters | 150 - 450 | 50 - 300 |

| Marine Applications | High reliability in harsh conditions | Winches, propulsion systems | 220 - 700 | 150 - 600 |

Maintaining double taper roller bearings is crucial for ensuring their long-term performance in heavy industry applications. Regular inspections should be conducted to check for signs of wear, misalignment, or contamination. Implementing a routine maintenance schedule allows operators to promptly address minor issues before they escalate into major failures, ultimately reducing downtime and repair costs.

Lubrication plays a vital role in maximizing the efficiency of roller bearings. It's essential to use the manufacturer-recommended grease or oil, as the right choice ensures optimal lubrication and protection against friction and heat buildup. Additionally, maintaining the correct lubrication frequency and quantity can significantly extend the bearing's lifespan. Operators should also monitor operating temperatures and vibrations, as deviations from normal ranges can indicate underlying problems that need immediate attention.

When using double taper roller bearings in heavy industry applications, several challenges and considerations must be addressed to ensure optimal performance and longevity. One significant challenge is the alignment of the bearings during installation. Proper alignment is crucial, as any misalignment can lead to premature wear and failure. Additionally, the installation environment must be carefully controlled to prevent contamination from dust, debris, and moisture, which can adversely affect the bearing's functionality.

Another important consideration is the selection of the right lubricant. Double taper roller bearings require specific grease or oil types that can withstand high loads and temperatures typical in heavy industrial settings. Inadequate lubrication can lead to increased friction, overheating, and eventual failure. Furthermore, regular maintenance and monitoring are essential to identify wear or damage early, allowing for timely interventions. Understanding these challenges is key to maximizing the advantages of double taper roller bearings in demanding applications.