In the ever-evolving landscape of manufacturing and transportation, the Bearing Wheel Roller industry stands at the forefront of innovation and efficiency. As we approach 2025, industry experts, like Dr. Emily Chen, a leading engineer at Global Bearings Corp, emphasize the importance of adapting to new trends. "The future of Bearing Wheel Rollers hinges on our ability to integrate advanced materials and smart technology," she asserts, highlighting the critical need for manufacturers to stay informed and agile.

As we delve into the top trends shaping the Bearing Wheel Roller market, it is essential to recognize the impending shifts that will influence everything from product design to operational processes. Environmental sustainability, improved load capacity, and the rise of automation are just a few of the key factors that will redefine how Bearing Wheel Rollers are produced and utilized. This evolution not only reflects the changing demands of consumers but also signifies a broader movement towards more efficient and sustainable industrial practices.

Understanding these trends will be vital for stakeholders aiming to maintain a competitive edge in the Bearing Wheel Roller sector. With experts like Dr. Chen leading the charge, it is clear that the future holds exciting prospects for innovation and growth within this critical industry.

In 2025, the bearing wheel roller industry is anticipated to undergo significant transformations driven by emerging technologies. The growing demand for high-performance bearings, particularly in heavy commercial vehicles, has prompted manufacturers to innovate and enhance their designs. According to recent market reports, the global market for tapered roller bearings is expected to witness substantial growth, primarily fueled by the rising production of SUVs and the need for improved load-bearing capabilities. This shift reflects a broader trend towards the adoption of lightweight materials and advanced engineering solutions within the sector.

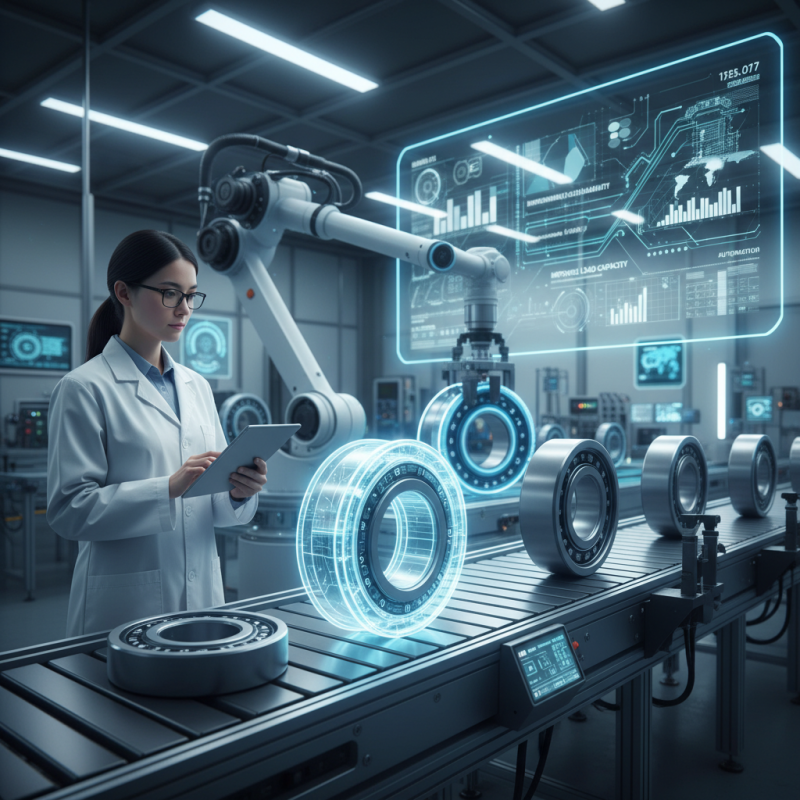

Technological advancements are also paving the way for smarter bearing wheel roller systems. The integration of IoT (Internet of Things) technologies enables real-time monitoring of bearing performance, which can drastically reduce maintenance costs and enhance operational efficiency. For instance, predictive analytics tools are increasingly used to anticipate failures before they occur, ensuring a smooth and reliable operation in various applications, from luggage systems to heavy-duty machinery. As manufacturers continue to focus on sustainability and durability, we can expect to see innovative designs that not only enhance functionality but also align with eco-friendly practices in the industry.

Sustainability is becoming a pivotal factor in the bearing wheel roller manufacturing industry as companies seek to align with global environmental standards. A recent report by MarketsandMarkets indicates that the green bearing market is projected to reach USD 20.8 billion by 2025, reflecting an annual growth rate of 8.4%. This shift towards sustainability entails the adoption of eco-friendly materials and production methods, which not only reduce carbon footprints but also enhance the overall lifecycle of bearing products.

Incorporating sustainable practices, manufacturers are increasingly focusing on using recyclable materials and energy-efficient processes. According to a study by Research and Markets, over 60% of leading companies in the bearing industry are investing in technology that minimizes waste during production. Additionally, the demand for electric vehicles, which rely heavily on high-performance bearing systems, is driving advancements in sustainability practices. As the automotive sector aims for net-zero emissions, the bearing wheel roller manufacturers are adapting by developing products that contribute to fuel efficiency and reduced environmental impact. This trend highlights the interconnectedness of sustainability and technological innovation in shaping the future of the bearing industry.

The demand for advanced bearing wheel rollers is being significantly driven by several key industries, including automotive, aerospace, and renewable energy. As vehicles become more sophisticated, the need for high-performance bearing systems that enhance efficiency and durability has never been greater. In the automotive sector, the shift towards electric vehicles requires components that can handle increased loads and operational speeds, making advanced bearing solutions essential for optimal vehicle performance.

Similarly, the aerospace industry is witnessing a surge in demand for lightweight and high-strength materials. Bearing wheel rollers are integral to various aerospace applications, ensuring smooth operation under extreme conditions. As aircraft manufacturers focus on innovation, the emphasis on reliability and precision continues to push advancements in bearing technology.

Tip: When selecting bearing wheel rollers for specific applications, consider factors such as load capacity, environmental conditions, and maintenance requirements. Ensuring that you choose the right type of bearing can significantly prolong the lifespan of machinery and enhance overall efficiency. By staying informed about the latest trends and innovations, industries can make better strategic decisions in their procurement processes.

This chart illustrates the demand trends for advanced bearing wheel rollers across key industries, highlighting projected growth from 2023 to 2025.

The landscape of bearing wheels and roller technology is rapidly evolving, particularly with the introduction of innovative materials that enhance performance. Manufacturers are increasingly turning to advanced composites and high-strength alloys that offer improved durability and lower friction. These materials not only contribute to the longevity of bearing rollers but also optimize their overall efficiency in various applications, ranging from automotive to aerospace.

When selecting bearing rollers, consider focusing on their material properties. High-performance polymers, for instance, can resist wear and corrosion, making them ideal for harsh operating environments. Additionally, the use of ceramics in bearing manufacturing provides excellent hardness and resistance to thermal expansion, which can drastically improve performance under high-load conditions.

TIP: Always check the specific material certifications and test data when purchasing bearing rollers to ensure they meet your operational requirements. Remember, the right material choice can significantly enhance the reliability and performance of your systems. Embracing these innovations not only fosters efficiency but will also give your applications a competitive edge in the marketplace.

| Material | Application | Advantages | Expected Trend by 2025 |

|---|---|---|---|

| High-Performance Plastics | Automotive and Aerospace | Lightweight, corrosion-resistant | Increased use due to weight reduction needs |

| Ceramics | Industrial Machinery | High durability, low friction | Rising demand for high-speed applications |

| Composite Materials | Sports Equipment | Enhanced strength-to-weight ratio | Growing popularity in performance sports |

| Stainless Steel Alloys | Food and Beverage Industry | Corrosion resistance, hygiene | Steady growth due to safety regulations |

| Graphene-Enhanced Materials | Electronics and Robotics | Superior strength, thermal conductivity | Emerging trend with potential for advancement |

The bearing wheel roller market is poised for substantial evolution by 2025, presenting both challenges and opportunities for industry players. One of the primary challenges lies in the increasing demand for sustainability and eco-friendly materials. Manufacturers must innovate to develop products that minimize environmental impact while maintaining performance efficiency. This requires investment in research and development to explore alternative materials and methods of production that reduce carbon footprints.

On the opportunity front, advancements in technology are set to transform the bearing wheel roller landscape. Automation and smart manufacturing processes hold the promise of enhanced efficiency and precision, catering to the evolving needs of sectors such as automotive and aerospace. Moreover, the rise of electric vehicles demands specialized bearing solutions, creating a niche market for companies ready to adapt to these new requirements. Embracing these technological trends will not only address market challenges but also position companies to capitalize on emerging opportunities in the fast-evolving bearing wheel roller market.